I will use while honing and checking ring gap

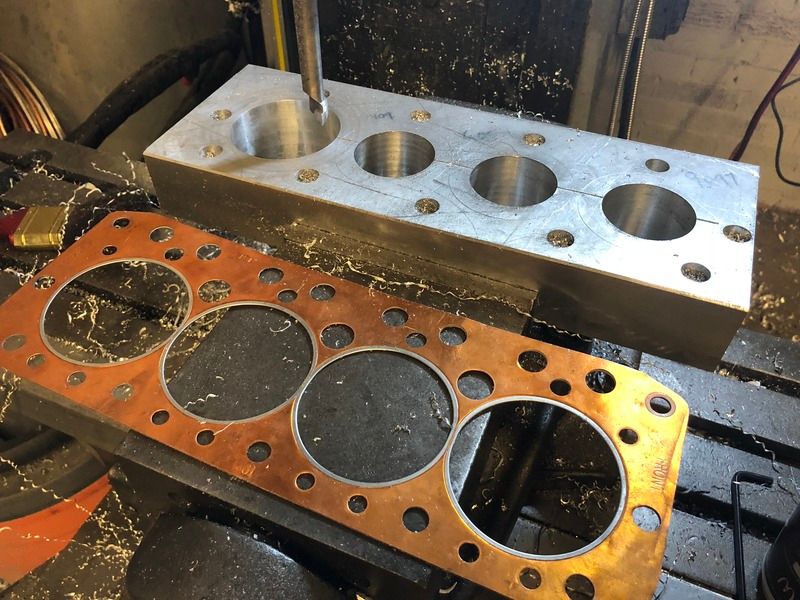

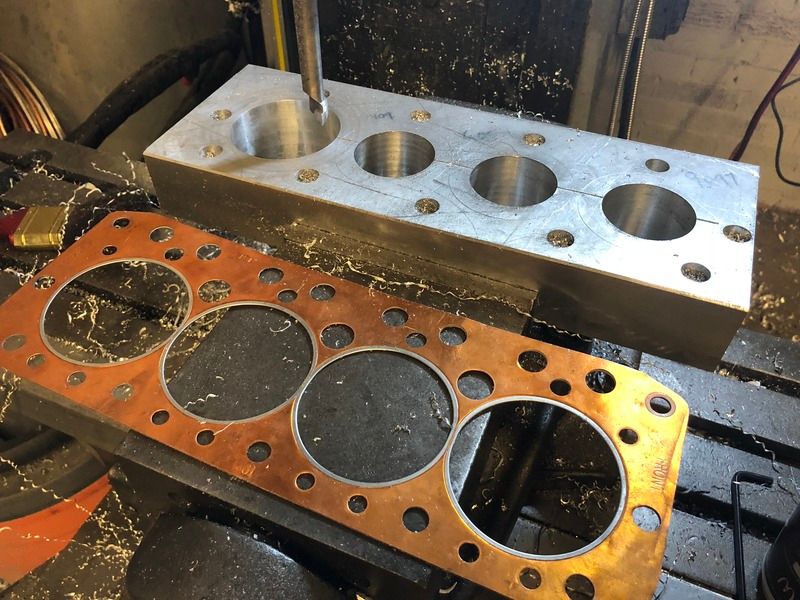

this plate gets bolted and torqued to the head using socket head cap screws and a head gasket

I am building a 1293 cc race motor for vintage racing

Is it just me or does everyone have a 1" paintbrush for wiping suds down the bore when boringJim1071 wrote:Hi making my own honing plate

I will use while honing and checking ring gap

this plate gets bolted and torqued to the head using socket head cap screws and a head gasket

I am building a 1293 cc race motor for vintage racing

I never thought of heating the blockCooperTune wrote: For those really reaching out there we once set up a small hot water heater a pump and circulated 180 degree water though the blocks when machining.

You mention a 1071 for vintage, what group do you race with? Steve (CTR)

Sorry, I misread your 1293, wishful thinking.

thank youatm92484 wrote:Nice work Jim. I made one from steel plate a few years ago.

atm92484 wrote: I did not have a mill at the time. A 2.75" holesaw leaves a hole that is a hair over 2.82" - perfect for +0.040" on a 1275. The rest was down to careful measuring and transferring holes from the head.

the price would be expensive if you only have one platejerry wrote:Could the plates be CNC laser or plasma cut to size? I wonder what the cost would be??

Jerry