Con rod repair

-

ian2988

- Basic 850

- Posts: 58

- Joined: Sat Mar 21, 2015 4:23 pm

Con rod repair

Hello.

I recently purchased at considerable expense, a nos set of 970 con rods(on 521 castings) I think they were originally a minispares reproduction. Unfortunately when I assembled the engine, I noticed that one of the pistons was tilted considerably lower on one side of the crown compared to the other(across the wrist pin).

After removing and measuring it would appear that the little end has been offset bored by around 4 or 5 thou which is obviously worse at the extremeties of the piston.

I am struggling to find another new rod so have a couple of ideas:

1. Have the little end corrected and a bush inserted back to correct size

2. Have the big end honed parallel with the little end.

Any suggestions and opinions for fixes would be much appreciated!

Thanks

Ian.

I recently purchased at considerable expense, a nos set of 970 con rods(on 521 castings) I think they were originally a minispares reproduction. Unfortunately when I assembled the engine, I noticed that one of the pistons was tilted considerably lower on one side of the crown compared to the other(across the wrist pin).

After removing and measuring it would appear that the little end has been offset bored by around 4 or 5 thou which is obviously worse at the extremeties of the piston.

I am struggling to find another new rod so have a couple of ideas:

1. Have the little end corrected and a bush inserted back to correct size

2. Have the big end honed parallel with the little end.

Any suggestions and opinions for fixes would be much appreciated!

Thanks

Ian.

- Spider

- 1275 Cooper S

- Posts: 4864

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 208 times

- Been thanked: 80 times

Re: Con rod repair

The normal practice is to bend the rod to make such corrections, but if it's really out, it could be sleeved.

Closing and Honing the Big End to correct the Little End would bring about other bigger problems.

Closing and Honing the Big End to correct the Little End would bring about other bigger problems.

-

ian2988

- Basic 850

- Posts: 58

- Joined: Sat Mar 21, 2015 4:23 pm

Re: Con rod repair

Hi thanks for the reply, is it done cold in a press(bending) or is there more to it than that?

Cheers

Ian

Cheers

Ian

- Vegard

- 1275 Cooper S

- Posts: 2042

- Joined: Mon Jun 28, 2010 1:33 pm

- Location: Norway

- Contact:

- Spider

- 1275 Cooper S

- Posts: 4864

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 208 times

- Been thanked: 80 times

Re: Con rod repair

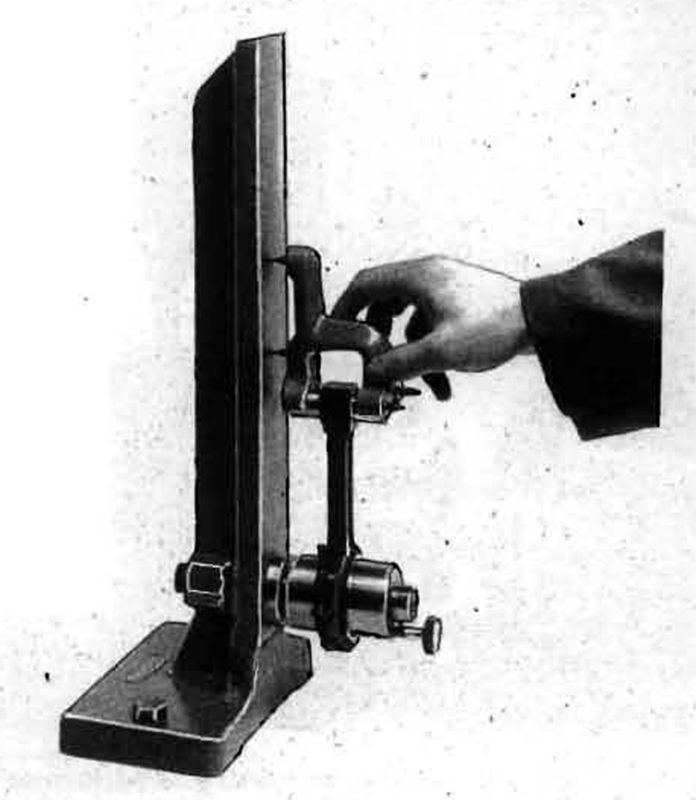

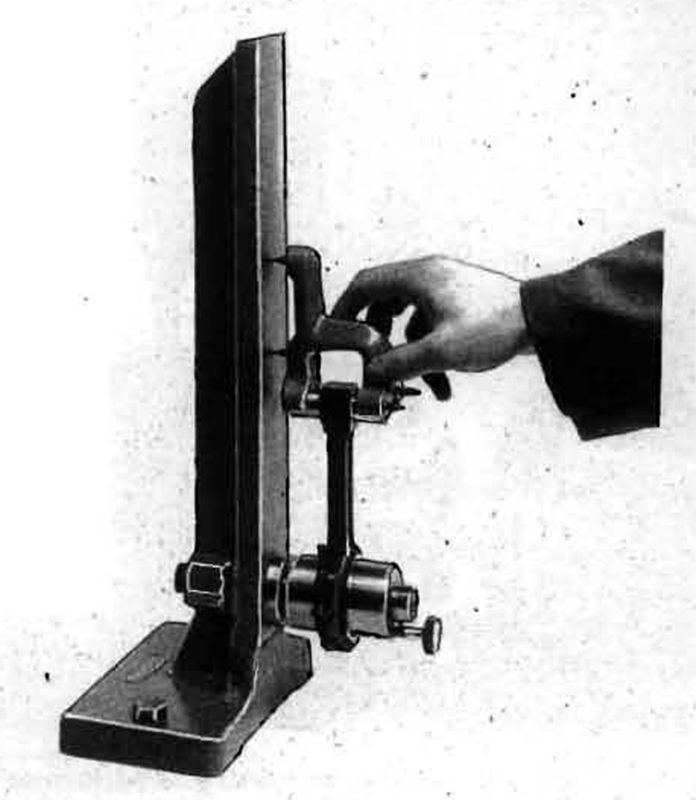

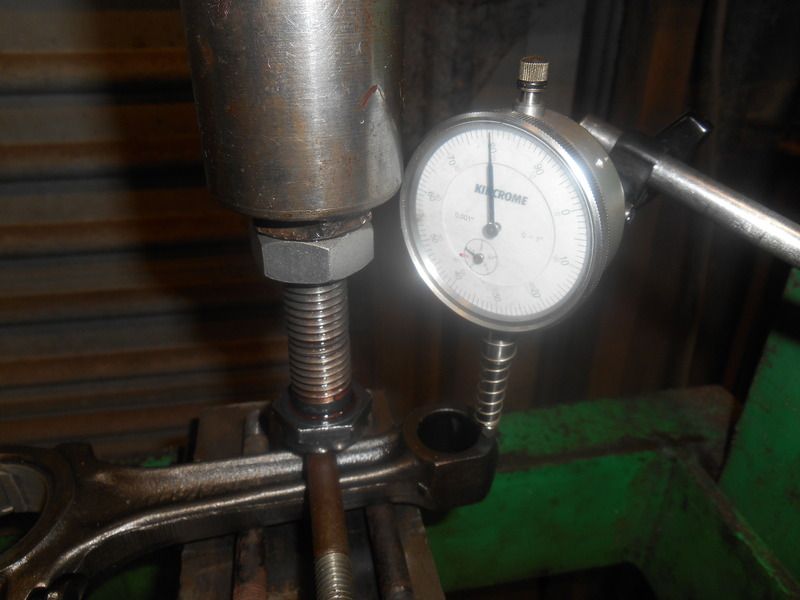

First thing to do would be to check the Rod for it's alignment. That's usually done on a Con Rod Alignment Jig

The part of it that the guy is holding is often referred top as a 'Sea Lion' because that's what it looks like! The way it's positioned there, Bend is being checked. Turn the Sea Lion around the other way and Twist can be checked.

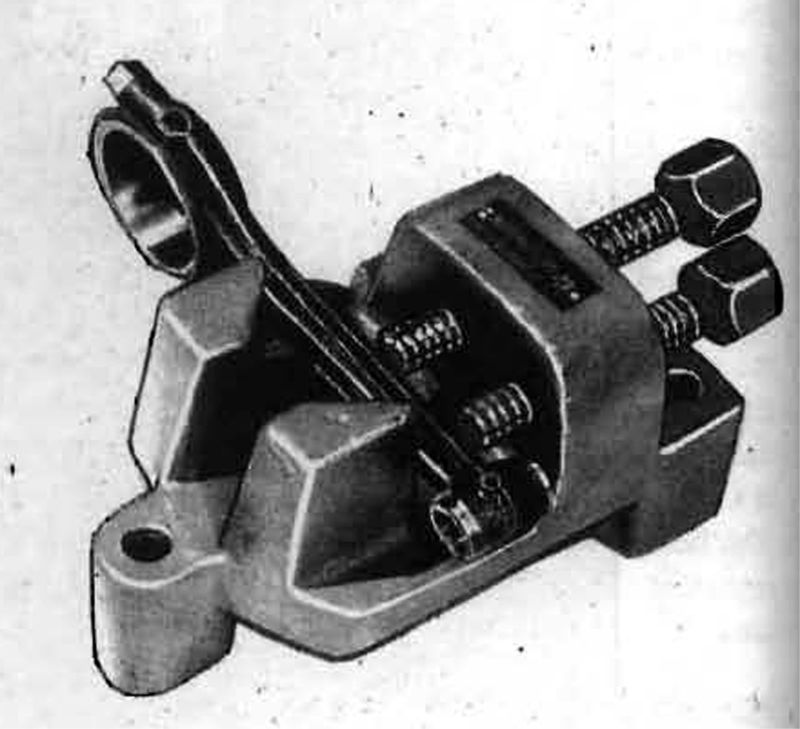

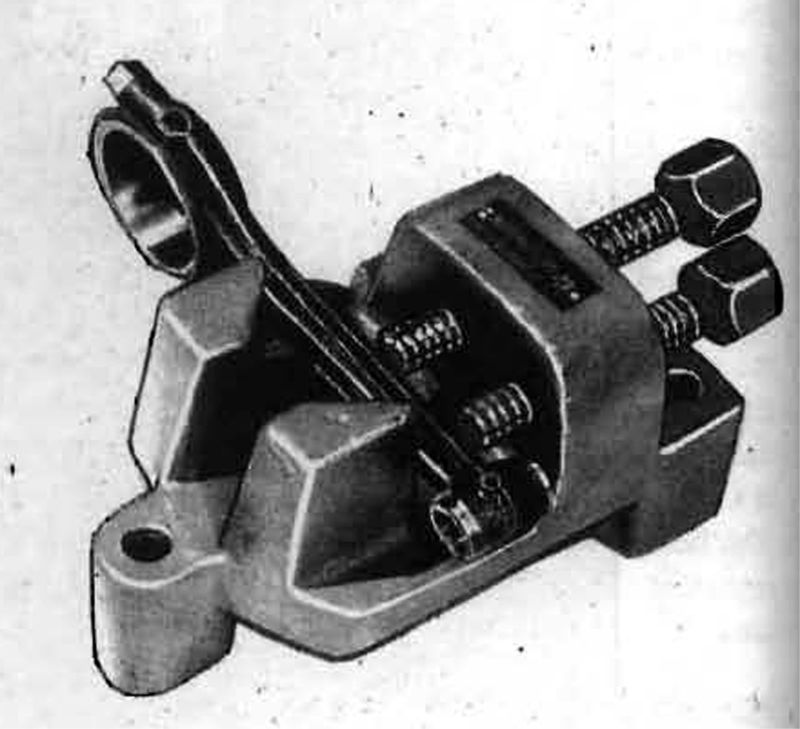

Then corrections are done in a Con Rod Straightening Press

Small light touches are usually all that's needed.

One other thing to check is that it's the Rod and not the Piston (hence why we check what's out of whack and where). Without exception, every AE piston I've had over the past 10 years up until I stopped using them, the Crowns were not parallel to the Gudgeon Pins, typically between 0.004 and 0.007"

However, I'm regularly correcting Rod by these figures and more - even new Rods. These are Forged Rods and can easily and happily take to bending.

The 'new age' after market Rods on the other hand, many are Sintered (not Forged) and while really really good in so many ways, they cannot be bent at all. Find a bent one and it's for the bin.

The part of it that the guy is holding is often referred top as a 'Sea Lion' because that's what it looks like! The way it's positioned there, Bend is being checked. Turn the Sea Lion around the other way and Twist can be checked.

Then corrections are done in a Con Rod Straightening Press

Small light touches are usually all that's needed.

One other thing to check is that it's the Rod and not the Piston (hence why we check what's out of whack and where). Without exception, every AE piston I've had over the past 10 years up until I stopped using them, the Crowns were not parallel to the Gudgeon Pins, typically between 0.004 and 0.007"

Verg, I agree that Float Pins are a better way to go, but not always justifiable.Vegard wrote:I'd sleeve them all and use floating wrist pins. Don't bend the rod that much!!!

However, I'm regularly correcting Rod by these figures and more - even new Rods. These are Forged Rods and can easily and happily take to bending.

The 'new age' after market Rods on the other hand, many are Sintered (not Forged) and while really really good in so many ways, they cannot be bent at all. Find a bent one and it's for the bin.

- 850man

- 998 Cooper

- Posts: 360

- Joined: Fri Nov 09, 2012 11:08 am

- Location: Melbourne, Australia.

Re: Con rod repair

Bending is not an option with a S rod, they are so hard that any attempt to bend them usually will break them. 2nd, the problem is at the little end of the rod, almost impossible to rectify with bending.

I would pin bore the rod and fit a bush, then machine the piston to suit circlips to retain the pin. Teflon buttons are another option, but make sure the correct type of teflon is used or it will fail.

I would pin bore the rod and fit a bush, then machine the piston to suit circlips to retain the pin. Teflon buttons are another option, but make sure the correct type of teflon is used or it will fail.

Restoration Specialist - https://www.facebook.com/linkautomotive

- Spider

- 1275 Cooper S

- Posts: 4864

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 208 times

- Been thanked: 80 times

Re: Con rod repair

You need more than that pussy rust bucket you call a car to bend them, 'idiot'850man wrote:Bending is not an option with a S rod, they are so hard that any attempt to bend them usually will break them. 2nd, the problem is at the little end of the rod, almost impossible to rectify with bending.

I would pin bore the rod and fit a bush, then machine the piston to suit circlips to retain the pin. Teflon buttons are another option, but make sure the correct type of teflon is used or it will fail.

If the Rods were that hard, you wouldn't be able to press the Pin in and if you did manage to, it would crack the Little End.

- Spider

- 1275 Cooper S

- Posts: 4864

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 208 times

- Been thanked: 80 times

Re: Con rod repair

Bend and Break eh? Mmmm,,,, take your lock-jaw and maybe you might learn something bone head.850man wrote:Bending is not an option with a S rod, they are so hard that any attempt to bend them usually will break them.

One Cooper S Rod, AEG-521 Forged in EN24

Not at all my prefered way as there's little feel however, set up thus

with a very light touch, we have 0.010" bend

and yes, the pressure was release

another light touch and we have 0,020"

After doing this, the rod was flipped over and set back.

They are only EN24, not the rust that your puss box is made from. They won't crack.

Big Rods, like these (on a standard 4' pallet) from a 125 litre straight 8 Daihatsu, we correct by machining the little end bush

It's not a good idea as a matter of course to bore, bush and machine the little end as it weakens one of the already weak parts of the rod - the little end.

-

CooperTune

- 1275 Cooper S

- Posts: 1331

- Joined: Sun Sep 22, 2013 1:47 pm

- Location: Coastal VA USA

- Been thanked: 10 times

Re: Con rod repair

Sorry I missed this one. Yes, by all means bend the rod to true. It is a big help having a rod vise and alignment jig. If most people knew what you learn in 25 years running a auto machine shop they would go back to horses. The new powdered rods with the cracked parting lines won't play but our rods you could tie in a knot and still run. A proper jig with a pin installed or polished to float in std rod checks for twist and bend. If you are worried any good shop can straighten and mag after but unless cracked before it won't be. Steve (CTR)

- 850man

- 998 Cooper

- Posts: 360

- Joined: Fri Nov 09, 2012 11:08 am

- Location: Melbourne, Australia.

Re: Con rod repair

Pfft, Moke owners.

Restoration Specialist - https://www.facebook.com/linkautomotive

-

ian2988

- Basic 850

- Posts: 58

- Joined: Sat Mar 21, 2015 4:23 pm

- Spider

- 1275 Cooper S

- Posts: 4864

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 208 times

- Been thanked: 80 times

Re: Con rod repair

Good work Ian, thanks for letting us know.

Chris, the Moke owner (who also owns 6 Minis, most of which are fast ones , but nothing rusty )

, but nothing rusty )

Chris, the Moke owner (who also owns 6 Minis, most of which are fast ones

-

CooperTune

- 1275 Cooper S

- Posts: 1331

- Joined: Sun Sep 22, 2013 1:47 pm

- Location: Coastal VA USA

- Been thanked: 10 times

Re: Con rod repair

Yes, it's nice when you hear when a plan works. Having retired from auto machine shop in 2000 I'm still welcome to drop in the shop and play any time I wish. Using the polishing belt on the crank grinder I polished a piston pin down enough to slide though a press fit rod. I press pistons off rinse the rods and check them for twist and true before any additional work is undertaken. I hope you found a shop who showed you how simple correcting rods is. Steve (CTR)