Page 1 of 1

Oil cooler mounting, Part 10,001

Posted: Sat Apr 26, 2014 9:07 am

by YMJ

Old one this but it's driving me mad.

Application is FIA AppK and frankly I'm so frustrated I now don't care who knows I am imcompetent at race preparation.

The only difference from a standard application is that the starter motor (RAC405) and alternator (RAC060) are from Powerlite. The grille is quickly detatchable, mounted only about 5mm further forward than standard.

Now....bearing in mind that one must not mount the cooler on the engine at one end and on the chassis at the other (even if mounted via rubber bobbins), how THE BLOODY HELL does one squeeze it in. I admit, I have not bothered to remove the engine to access the front of the subframe (from behind) but it cannot be beyond the wit of man to get the cooler into the front of the car, retain the standard(ish) grille and still leave enough clearance betweeen grille and moving engine part (starter motor/distribrutor/oil filter).....can it?

Any photos from current or historical rivals greatly appreciated. Swifty was running a 16 row cooler at one point - how in the name of blue f**k did he do that??

Re: Oil cooler mounting, Part 10,001

Posted: Sat Apr 26, 2014 9:14 am

by rich@minispares.com

its easy (LOL)

you just have to pull the bottom of the grille out and make sure the powerlead on the front of the starter doesn't hit the cooler.

I say easy, it took me fricking hours and trying every single option of cooler hoses minispares sell before it all fell into place

Re: Oil cooler mounting, Part 10,001

Posted: Sat Apr 26, 2014 10:48 am

by YMJ

Thanks Rich, I've sent you an email and shall phone you shortly.....if you're at work today.

By-the-way, does the springiness in the Minispares mountings negate the need for rubber bobbin vibe insulation?

Re: Oil cooler mounting, Part 10,001

Posted: Sat Apr 26, 2014 8:22 pm

by Spider

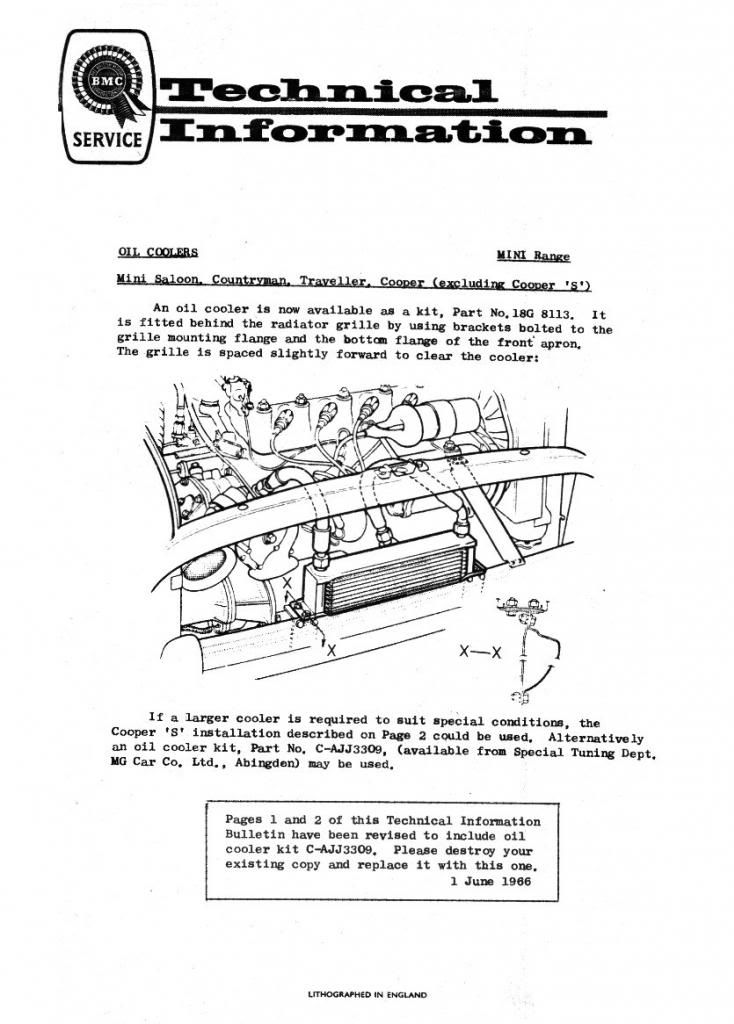

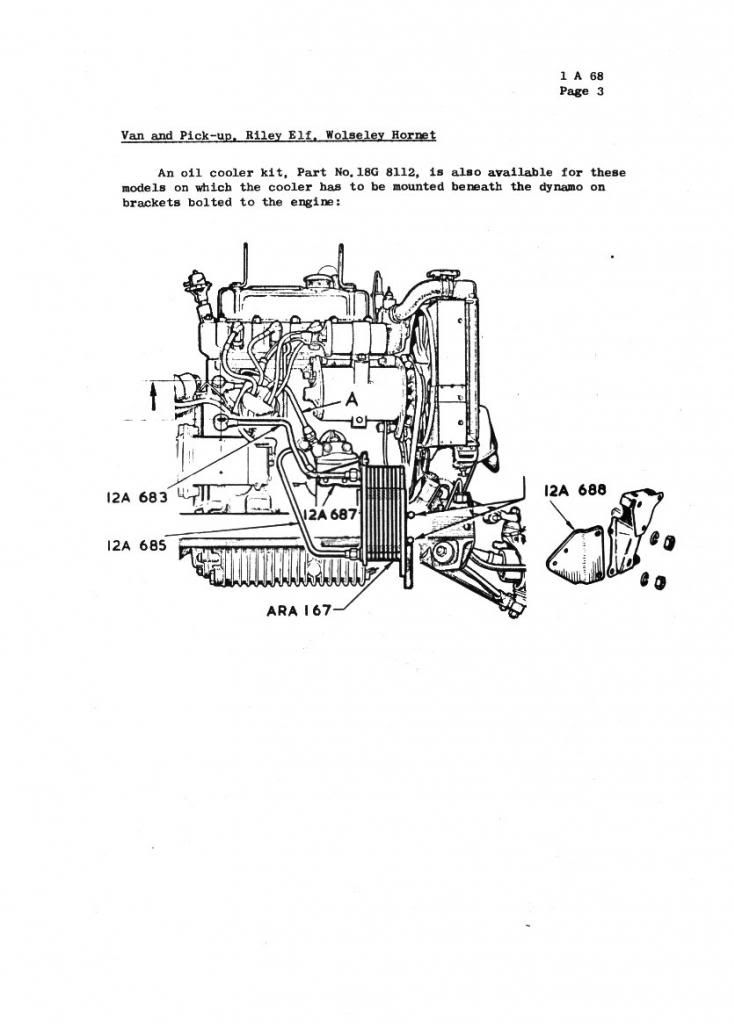

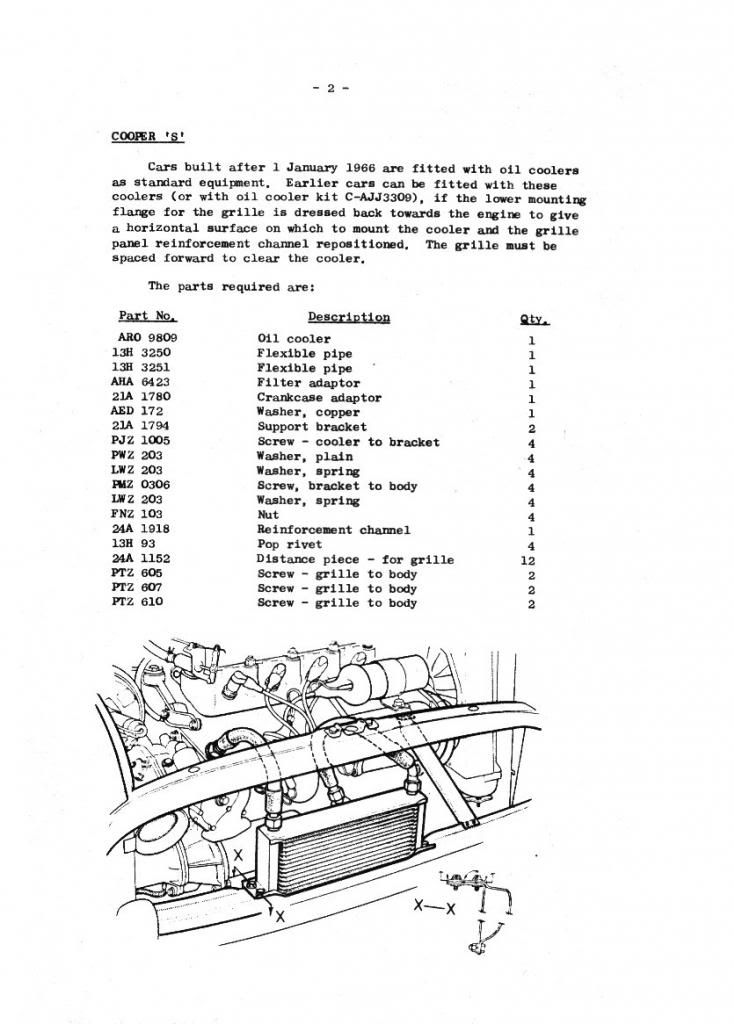

Here's some factory info which may help;-

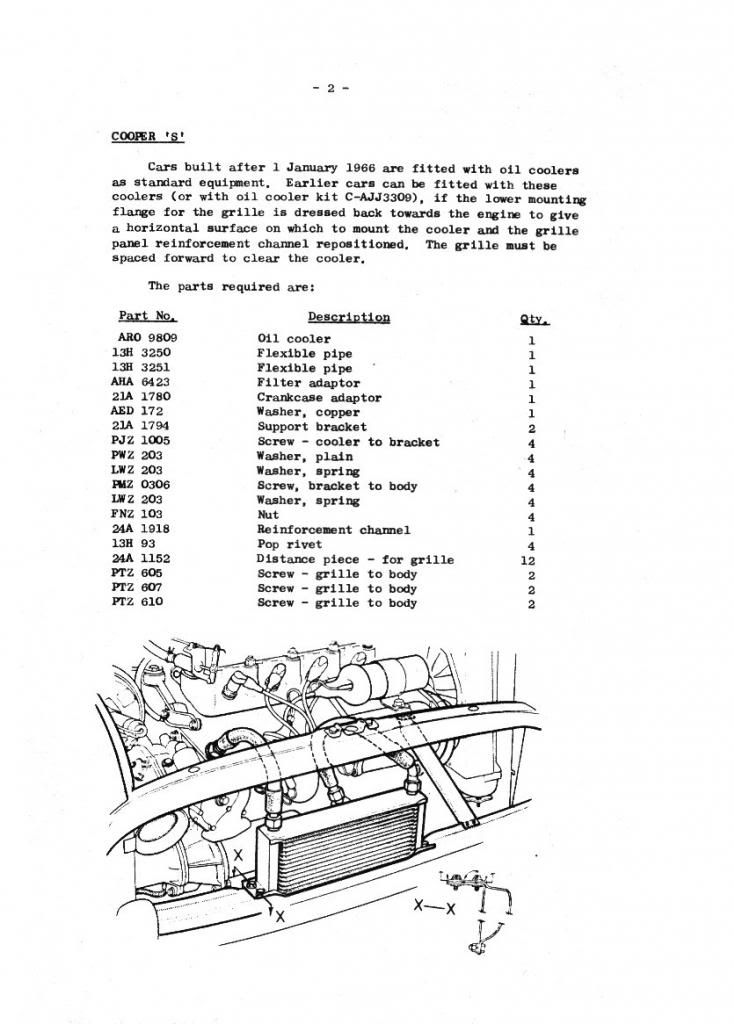

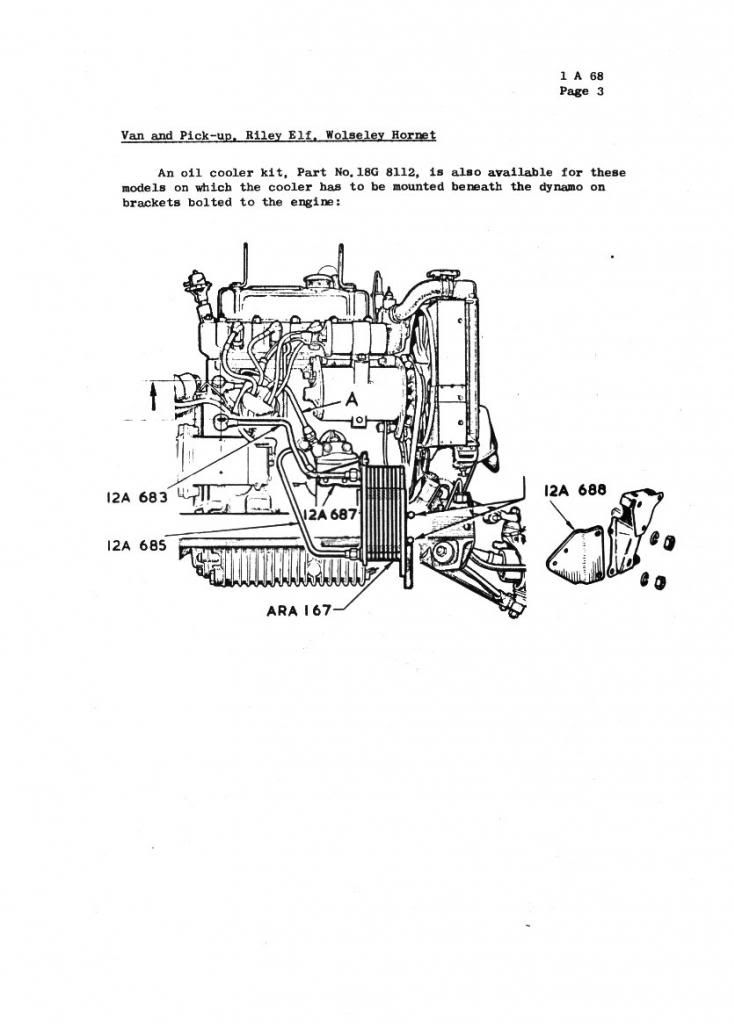

and just for an interest item, another type that was offered;-

which I think I recall someone saying was factory fitted to the Cooper S for a very short time, would this be right?

Re: Oil cooler mounting, Part 10,001

Posted: Sat Apr 26, 2014 11:23 pm

by youngres

Swifty was running a 16 row cooler at one point - how in the name of blue f**k did he do that??[/quote]

If you look closely, Nick swift fixes the oil cooler to the front of the subframe not the front panel. That way you could happily run a 16 row cooler.

Robert

Re: Oil cooler mounting, Part 10,001

Posted: Sun Apr 27, 2014 12:17 am

by Pete

Spider wrote: which I think I recall someone saying was factory fitted to the Cooper S for a very short time, would this be right?

The upright cooler was indeed the factory option on early cars and rarely ever specified.

Re: Oil cooler mounting, Part 10,001

Posted: Mon Apr 28, 2014 10:16 pm

by YMJ

Thanks all.

I eventually plumped for vertically mounting it (standard Mocal 13 row jobby) between the alternator and distributor.

Here's how and it makes a lot of sense in an already cramped environment.....

Remove grille, diz cap and alternator after you have dropped in the cooler to see how it looks and how much clearance you can get between the front panel and the oil filter housing (you don't have to worry about the dizzy cap or the Brise race alternator because it fits niceley in between the two). Also the biggest problem I had when trying to locate it horizontally was the blasted black plastic solenoid lead cover on the starter motor, NOT the big power stud - that can be ground down quite a bit shorter).

Drill one hole in the top of the front of the subframe to locate your general purpose rubber bobbin. Using a nicely cut piece of ally angle, you can fit the oil cooler to the bobbin. So that's the bottom bracket sorted.

The top is pretty much the same except access is a lot easier. Drill a hole in the top of the front panel and again using a sympathetically cut piece of ally angle you can fix the top of the cooler close enough to the front panel leaving a yawning chasm between it and the potentially destroying oil filter housing.

Thus I have the cooler fitted to the subframe at the bottom and to the bodyshell diagonally opposed at the top. THis means the engine can rock all it likes under heavy engine breaking and the cooler will not fracture. It is also insulated from vibration on the rubber mounts. When fitting the oil pipes make sure there is as little torsional tension as possible - make sure all four connectors are nice and loose and tighten them up gradually in turn.

You now have a stress-free oil cooler that will get a good draft of incoming air and is a pretty long way away from that engine. And you don't have to compromise the grille position by spacing it forwards.

The only downside is that it doesn't look very neat - I'd much rather have it fitted horizontally as in Spider's drawings that he kindly put up. But to get the exact clearances right without butchering (too much) the bodywork means engine out and lots of time and lots of measuring and re-measuring.

This won't be the solution for everyone but I'm happy for the moment.