Page 1 of 1

front hub nut torque

Posted: Sat Apr 12, 2014 9:47 pm

by YMJ

OK, so I need to retighten the front hub nut on the 'S' and the "book" says 60ft lbs but that seems a tad slack to me. Is this right?

I know that if you go too tight you stand a chance of the disc, hub flange and wheel falling off at high speed but the same goes when too loose. Any anecdotal advice?

Re: front hub nut torque

Posted: Sat Apr 12, 2014 10:14 pm

by Andrew1967

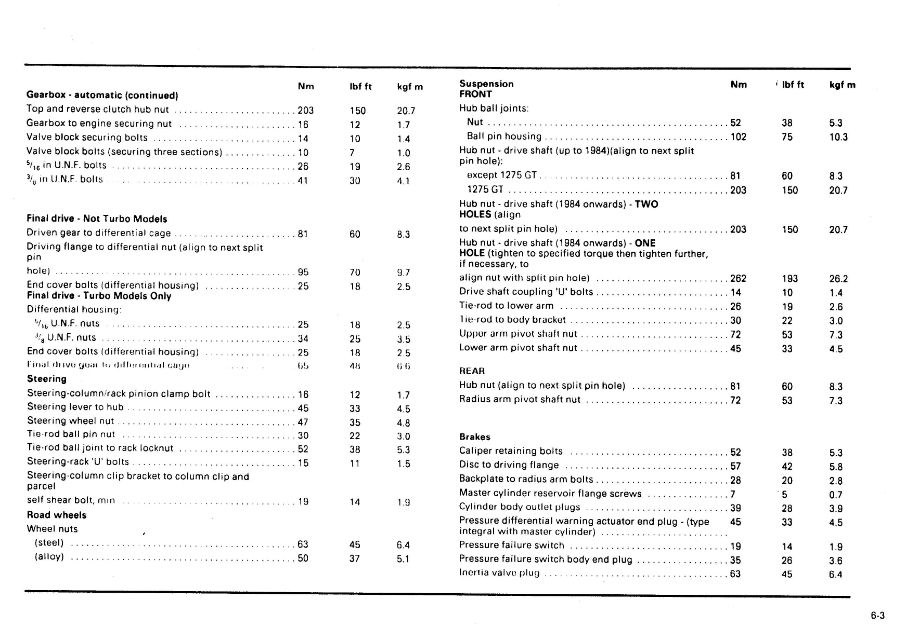

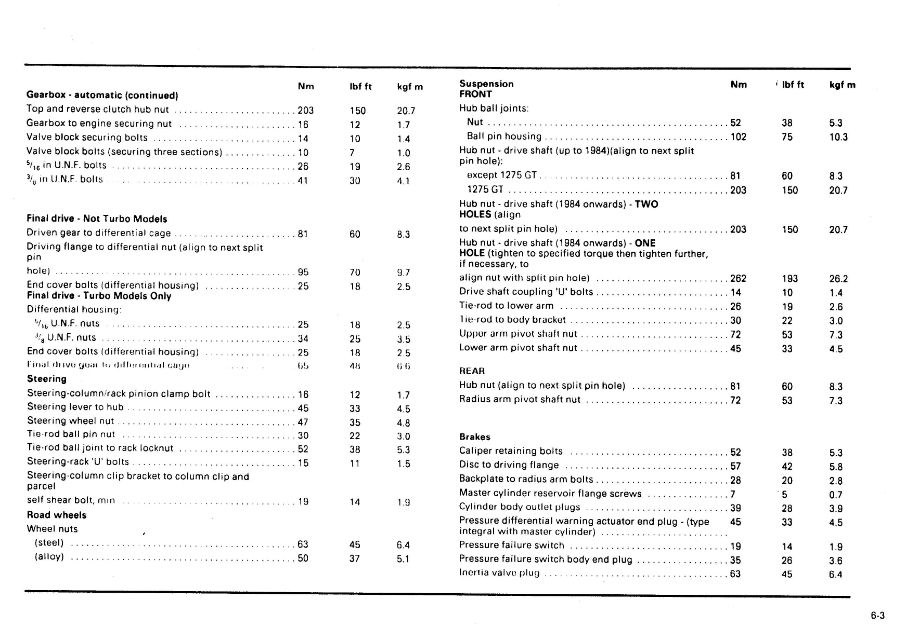

I thought it was 150 ft/lbs and align to next hole, but stand to be corrected.

60 ft/lbs is for the drum brake and 7" disc brake cars.

Re: front hub nut torque

Posted: Sat Apr 12, 2014 10:19 pm

by Spider

60 ft/lbs is actually for Drum Brake and 7" Cooper Discs. These had a smaller shafted CV, I can't recall the thread size (9/16" UNF?), but the AF size of the nut was 15/16"

7.5" and 8.4" Discs have a bigger shafted CV, the thread is 7/8" UNF (although there are some metric ones also getting about) and the AF size of the nut is 1-5/16" (or 34 mm in the case of the metric ones). This is were it gets a bit murky though.

Some of the later CVs, generally identified by having a single hole, Brands such as Metelli and Transtec fall in to this category, for the split pin are torqued to 197 ft/fbs, then to the next slot on the nut. I have found that wheel bearing life has been greatly extended using these CVs as a result of the added clamping force on the assembly.

Others and early ones were torqued to 150 ft/lbs. Sorry, I am unable to offer much guidance as to picking which CV is done to 150 and which to 197. If in doubt, only torque to 150 ft/lb, then check again after about 50 km and then again at 500 km.

There is also some later advice that the tapered washer should initially be removed and a hardened flat washer put in it's place, then torqued up, then carefully undo, remove the flat washer, replace the tapered washer and go again. IMO, this probably only came about when the tapered washer was being reused and was in un-serviceable condition, If it's in good order, you won't have a problem. I've never done it with using a flat washer first and never had a problem.

Re: front hub nut torque

Posted: Sat Apr 12, 2014 11:00 pm

by YMJ

Thanks fellas. I thought I was going mad!

I've been titting about with Minis for over 30 years and racing them for 20 and there I was torquing up the nut, couldn't remember the setting, looked in the book, saw 60ft lbs and

knew it wasn't right. I shall set the torque wrench to FT !

NB. I now have acquired quite a large collection of tapered washers - in my experience, you tighten the nut, check to see if the holes line up and if they don't try another taper washer. Simples

Re: front hub nut torque

Posted: Sun Apr 13, 2014 11:17 am

by ianh1968

Spider wrote:the thread is 7/8" UNF (although there are some metric ones also getting about)

and the AF size of the nut is 1-5/16" (or 34 mm in the case of the metric ones).

I have not seen any metric

threaded CV's, all the ones that I have

seen so far have been UNF. Or at least I am pretty sure they have.

I have been able to swap 34mm nuts for 1-5/16" ones and the thread

has always been the same...

Many do now have the metric A/F sized nut , it all depends on which size

hex bar is available the cheapest when the manufacturers make the nuts.

So you could get either 1-5/16" or 34mm. I get a lot of my stuff from

MiniSpares Centre and most of the recent CV's I've bought have had

34mm nuts. They do also sell the "correct" size but you'll obviously

have to pay extra to get them.

These sizes are bit of a PITA as you now need to have TWO sockets...

Back to the original question of "how tight?", my torque wrench only

goes up to 150lb/ft anyway, so I just wind the nuts up to the maximum

the wrench will go, then any further to get the hole alignment using my

3/4" drive breaker bar.

YMJ wrote:I now have acquired quite a large collection of tapered washers

Ditto with the nuts, the thread start position compared to the slots will

differ also, so there are a couple of methods to get the slot/hole

alignment other than going really tight when you don't want to.

Ian

Re: front hub nut torque

Posted: Sun Apr 13, 2014 10:00 pm

by 2ramp3

150 lbs/ ft is the correct torque for front hub nut and tighten to get split pin to fit but if you want to to get it precise [it doe,nt hurt anything using afore mentioned method] then torque up nut mark split pin grove on hub remove nut slide out cv joint and move hole in cv round to mark on hub job done

Re: front hub nut torque

Posted: Mon Apr 14, 2014 3:00 am

by Spider

Ianh1968,

I did buy a Mini that was fitted with the Metric Threaded CVs that I spoke of, it was a ripe pain in the backside. The threads were M22 x 1.5. Clearly they came from an aftermarket supplier, I've also seen a few similar ones being offered on ebay in recent years. I don't have those CVs anymore, I gave them to a mate, I'll ask if he still has them. I didn't know of those Metric / Imperial Nuts, until you mentioned them!

I first found out about the different torque settings for the late CVs from the Mini Spares webpage (it's changed now from what it was, but the info is basically still there);-

http://minispares.com/product/Classic/D ... ic/cv.aspx

After finding that info, I confirmed it from the Rover Manual AKM 6353, page 6-3;-

and I found reference that that flat washer idea in a Haynes manual, Mini Spares sell those washers;-

http://minispares.com/product/Classic/A ... ic/cv.aspx

Re: front hub nut torque

Posted: Mon Apr 14, 2014 8:46 am

by Smiffy

Those washers where designed, to help idiots fit a part they obviously shouldn't be touching.

Re: front hub nut torque

Posted: Mon Apr 14, 2014 8:48 am

by rich@minispares.com

the 34mm nuts minispares sell are still imperial thread

the 34mm is the size of the socket required to fit the metric barstock that the nuts are made of

Re: front hub nut torque

Posted: Mon Apr 14, 2014 2:14 pm

by ianh1968

Spider, these are what we need:

http://www.minispares.com/product/classic/BTA249.aspx

It's a bit sad that they are sold at DOUBLE the price of the hybrid

UNF/34mm nut, but there you go...

Regarding the M22x1.5 thread. Another potential PITA as we would

then need spare nuts in both threads as well as TWO sockets...

Fortunately, I have not come across the "totally french" variety, yet!

The difference in torque looks to be dependent on the number of

split-pin holes the CV has and whether it is pre or post 1984.

Oddly, the one which would be weakest due to having TWO holes

in it is the one which is supposed to be done up tighter?

I am not sure how this would all work as surely all CV's made now

would be made post '84 regardless of the number of holes. Maybe

there is some kind of engineering reason for some requiring

193lb/ft as opposed to 150lb/ft.

As I said before, my wrench only goes up to 150lb/ft anyway, so

the bottom line is that mine just get done up "really" tight.

TOP TIP:

Make sure when you stick the CV joint through the drive hub that

the split pin holes do NOT line up with the wheel-nut studs. It can

make it a bit difficult to the this pins in or out...

Ian

Re: front hub nut torque

Posted: Mon Apr 14, 2014 6:31 pm

by GraemeC

I've never understood why the number of split pin holes makes the slightest bit of difference to the required/advised torque.

When done up the holes aren't in the stressed area and so that part of the shaft should have minimal loading. Therefore the 'weakening' due to a second hole would be irrelevant (and I'm sure the pin would fail long before the shaft).

Surely the torque is to provide the correct loading on the wheel bearings, which are the same in both applications!? So the torque should be the same?

Re: front hub nut torque

Posted: Mon Apr 14, 2014 9:03 pm

by Spider

ianh1968, yes, they are the type of nut I fit! Crickey, they are (mostly) an imperial car, then to go mixing up stuff like that in to the mix. Not my cuppa tea!

It would seem that the 1 hole / 2 hole for the split pin is only used as a method of distinguishing between the two types. I have found when machining them the later ones are a different grade of steel and / or have different heat treatment. The later ones are definitely a considerably higher tensile material (I have found when torqued up, they have less stretch in them) and quite likely other improved properties. I had to get some special cutting tips to be able to machine these.

Re: front hub nut torque

Posted: Tue Apr 15, 2014 2:56 am

by ianh1968

GraemeC wrote:Therefore the 'weakening' due to a second hole would be irrelevant

The 'weakening' was not really intended to be a serious reason, just a "finger up the backside"

reason, in the absence of any immediately apparent sensible answer....

GraemeC wrote:Surely the torque is to provide the correct loading on the wheel bearings,

which are the same in both applications!? So the torque should be the same?

I think that Spider has probably hit this one on the head with the different spec materials

and/or heat treatments requiring the different torque settings.

Ian

Re: front hub nut torque

Posted: Tue Apr 15, 2014 9:31 pm

by GraemeC

Not convinced - the material spec and heat treatment of the CV doesn't change the amount of load the bearings should have.

Re: front hub nut torque

Posted: Tue Apr 15, 2014 9:48 pm

by Spider

GraemeC wrote:Not convinced - the material spec and heat treatment of the CV doesn't change the amount of load the bearings should have.

The Pre-load of the bearings is fixed by the matched spacer that comes with the bearing set. Increasing the torque (and therefore the clamping force) reduces chaffing between the bearings and the spacer.

Re: front hub nut torque

Posted: Tue Apr 15, 2014 10:20 pm

by GraemeC

OK- I'm coming round to your thinking!

So....are all aftermarket CVs maces to same material spec and treatment as the OE ones? And are there single and double hole CVs still available with differing specs?

Re: front hub nut torque

Posted: Tue Apr 15, 2014 11:16 pm

by Spider

GraemeC wrote:

So....are all aftermarket CVs maces to same material spec and treatment as the OE ones? And are there single and double hole CVs still available with differing specs?

I seem to recall that the original Cooper S CV was manufactured in those days by Hardie Spicer, these went under the factory P/N of 27H7567. There was propobably a few other OEMs along the way too. Then some time in the mid 80's, Rover decided on an up-grade, I think the OM P/N was GCV1013. It appears that these were manufactured by Metelli.

These days, the Metelli ones seem thin on the ground, however there are other sold under the name of Transtec, which as best as I can determine are equal to the Metelli ones (I'm actually convinced that they are in fact coming out of the same factory).

I have come across one CV, brandless, that did only have a single split pin hole. It was clearly neither a Metelli nor Transtec. Without testing it, I couldn't say what the material spec / treatment was and for the end user, what the correct nut torque should have been. I guess, play it safe, only go to 150 ft/lbs.

I'll also add that for most normal road use, experience has shown me that the 2 hole CVs will be quite fine. Certainly in my own Minis, I've had few issues with them even when pressed. On our (Big Wheel) Mokes it's a whole different ball game though, regardless of how they are used.

Outside of those that are OEM who knows?

Having said that, I have come over many many Brands of aftermarket CVs (most nameless) and in general, I'd say most were quite OK, easily as good as the Hardie Spicer ones, though there were a few that clearly were not.

I'd suggest if buying CVs, buy from a reputable source, some will even have fitting instructions.