Clutch travel & adjustment question again

-

AndyPen

- 1275 Cooper S

- Posts: 3841

- Joined: Mon Jul 24, 2017 5:55 pm

- Location: South Wales

- Been thanked: 22 times

Clutch travel & adjustment question again

So, my wife's mini (64 SDL with a 970S in it) had a clutch job done a while back and I've only now really started to play with it again, simply because the release is right at the bottom of the pedal. The car has new everything really, hydraulic reservoir and new slave, new lever arm with cotter pins, new release bearing on a new plunger and new clutch kit with diaphragm.

The engine has done about 3k on a reground 10 / 10 crank and had new thrusts etc. Oil pressure is around 65 when hot. I cannot detect any side movement at the pulley end of the crank, so hope those thrusts are fine.

I checked the adjustment as per the manuals again, and according to some you get the lever pulled out on the pedal and tighten the throw out bolt so that it touches the casing with the pedal depressed, then give it a flat or so extra so there is no pressure on the crank and its thrusts. Then lock it up accordingly. Top adjustment also done with spring off and correct gap.

Changing gears then becomes very difficult like it isn't disengaging, so I unscrewed the throw out, loosed it a bit and it improved the pedal slightly. I am now wondering if I am getting sufficient travel from the arm so will take another look at that soon.

I know that some people are now fitting a washer behind the release bearing to give it a little extra travel, so that is in my mind but before I dismantle it, would appreciate any thoughts anyone might have please?

Am I missing something here??

The engine has done about 3k on a reground 10 / 10 crank and had new thrusts etc. Oil pressure is around 65 when hot. I cannot detect any side movement at the pulley end of the crank, so hope those thrusts are fine.

I checked the adjustment as per the manuals again, and according to some you get the lever pulled out on the pedal and tighten the throw out bolt so that it touches the casing with the pedal depressed, then give it a flat or so extra so there is no pressure on the crank and its thrusts. Then lock it up accordingly. Top adjustment also done with spring off and correct gap.

Changing gears then becomes very difficult like it isn't disengaging, so I unscrewed the throw out, loosed it a bit and it improved the pedal slightly. I am now wondering if I am getting sufficient travel from the arm so will take another look at that soon.

I know that some people are now fitting a washer behind the release bearing to give it a little extra travel, so that is in my mind but before I dismantle it, would appreciate any thoughts anyone might have please?

Am I missing something here??

- Peter Laidler

- 1275 Cooper S

- Posts: 6133

- Joined: Sat Jul 15, 2017 5:35 pm

- Location: Abingdon Oxfordshire

- Has thanked: 27 times

- Been thanked: 29 times

Re: Clutch travel & adjustment question again

I think that you are missing something Andy......., but I can't quite put my finger on it on the basis that you wouldn't miss something obvious.

What I am thinking is that I agree with you that there might not be the correct leverage at the clutch arm, due to wear. For a few years I was using a slightly extended slave cylinder push rod to get a bit of extra leverage. That was until I worked out the mathematics and leverages. Renewed or re-bushed all the working parts......

The 5:1 lever ratios at the clutch arm is pretty dramatic when there's even a bit of wear on any of the clutch lever train

What I am thinking is that I agree with you that there might not be the correct leverage at the clutch arm, due to wear. For a few years I was using a slightly extended slave cylinder push rod to get a bit of extra leverage. That was until I worked out the mathematics and leverages. Renewed or re-bushed all the working parts......

The 5:1 lever ratios at the clutch arm is pretty dramatic when there's even a bit of wear on any of the clutch lever train

-

Polarsilver

- 1275 Cooper S

- Posts: 2803

- Joined: Fri Jan 15, 2016 12:22 pm

- Location: Silverstone not far away

- Has thanked: 3 times

- Been thanked: 17 times

Re: Clutch travel & adjustment question again

Have struggled with this issue off & on for the past Sixty Years .. now my solution even after replacing ALL parts & removing the wear issues & becoming much wiser with clutch set up issues

can i suggest you buy a Minisport "adjustable" Pushrod (circa £18 to buy) .. this will allow you to adjust / set up the Clutch Pedal travel to get a clutch bite point that just suits you .. worked for me

can i suggest you buy a Minisport "adjustable" Pushrod (circa £18 to buy) .. this will allow you to adjust / set up the Clutch Pedal travel to get a clutch bite point that just suits you .. worked for me

- LarryLebel

- 998 Cooper

- Posts: 541

- Joined: Sat Feb 15, 2014 12:02 am

- Location: North Vancouver BC

- Spider

- 1275 Cooper S

- Posts: 4775

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 59 times

- Been thanked: 15 times

Re: Clutch travel & adjustment question again

Can I suggest bottoming out the Piston in the Slave Cylinder and then giving it a small re-bleed. Because the bleed nipple is almost over the hose, there remains a small air pocket in the slave. Bottoming out and holding the piston in that position reduces that air pocket to as small as can be.

Also, check your clutch pedal where it enters the back of the bulkhead, you don't want anymore than about 1/8" - 3 mm clearance there. Anymore and you have lost travel before you start.

Also, check your clutch pedal where it enters the back of the bulkhead, you don't want anymore than about 1/8" - 3 mm clearance there. Anymore and you have lost travel before you start.

-

Aussie Bill B

- 850 Super

- Posts: 181

- Joined: Fri Dec 27, 2013 10:19 am

- Location: Camden NSW AUSTRALIA

Re: Clutch travel & adjustment question again

So, I am not alone...!Polarsilver wrote: ↑Thu Nov 14, 2024 10:30 pm Have struggled with this issue off & on for the past Sixty Years .. now my solution even after replacing ALL parts & removing the wear issues & becoming much wiser with clutch set up issues

can i suggest you buy a Minisport "adjustable" Pushrod (circa £18 to buy) .. this will allow you to adjust / set up the Clutch Pedal travel to get a clutch bite point that just suits you .. worked for me

Ended up with the same solution - welded extra length onto the pushrod to move the piston in the slave cylinder further towards the centre of its travel and away from hitting the circlip.

I assume that bending the lever arm achieves the same result, although not as discrete.

The excess adjustment needed to set up the clutch always seems to be after an engine rebuild or clutch replacement, which somehow is moving the flywheel (and also the driven plate and pressure plate attached to it) up the taper and away from the throw-out bearing. That might be why a longer pushrod or the large washer behind the throw-out bearing is suggested to help regain lost adjustment travel.

-

AndyPen

- 1275 Cooper S

- Posts: 3841

- Joined: Mon Jul 24, 2017 5:55 pm

- Location: South Wales

- Been thanked: 22 times

Re: Clutch travel & adjustment question again

Thanks everyone, I am glad that I am not alone here.

I neglected to mention that the pedal has a new cotter pin as well, and that the pedal hole was pretty good so it didn't appear to need a bush (or replacement). I will get the driver seat out and stick my nose up there under the pedal again for another check. The clutch arm is also the new slightly thicker one, but worth checking in case there is a fracture or anything Larry.

I think what you say about the bleeding is worth a follow up with my easi bleed as well Spider, and the point about the flywheel moving up the taper might help to explain it Bill. I did wonder why so many people seem to have fitted an adjustable push rod, maybe this is it???

All stuff I can do without major dismantling- so thanks for the prompt inputs folks.

I am also about to fit the clutch on the 1071 motor on my bench, so will be double checking everything on that too!!!

I neglected to mention that the pedal has a new cotter pin as well, and that the pedal hole was pretty good so it didn't appear to need a bush (or replacement). I will get the driver seat out and stick my nose up there under the pedal again for another check. The clutch arm is also the new slightly thicker one, but worth checking in case there is a fracture or anything Larry.

I think what you say about the bleeding is worth a follow up with my easi bleed as well Spider, and the point about the flywheel moving up the taper might help to explain it Bill. I did wonder why so many people seem to have fitted an adjustable push rod, maybe this is it???

All stuff I can do without major dismantling- so thanks for the prompt inputs folks.

I am also about to fit the clutch on the 1071 motor on my bench, so will be double checking everything on that too!!!

- Peter Laidler

- 1275 Cooper S

- Posts: 6133

- Joined: Sat Jul 15, 2017 5:35 pm

- Location: Abingdon Oxfordshire

- Has thanked: 27 times

- Been thanked: 29 times

Re: Clutch travel & adjustment question again

Bleedin' clutches........ That's another thing. For heavens sake, give yourself a break Andy and fit a remote bleed valve to your car. Invented by one of our fellow forumers and a godsend for the start and finish of any clutch woes and fixes. SO simple and SO bluddy convenient.

Talking of adjustable push rods....... Good idea but being a cheapskate, I just extended mine and took heed of Spider Chris's bleed suggestion - with the help of the remote bleeder - if you'll excuse the phrase!

But once I really set about my system, once and for all, by eliminating all play and accumulative error and bleeding it through thoroughly, I found that I didn't need the old extended push rod

Talking of adjustable push rods....... Good idea but being a cheapskate, I just extended mine and took heed of Spider Chris's bleed suggestion - with the help of the remote bleeder - if you'll excuse the phrase!

But once I really set about my system, once and for all, by eliminating all play and accumulative error and bleeding it through thoroughly, I found that I didn't need the old extended push rod

-

gsamps

- Posts: 10

- Joined: Thu Sep 21, 2017 9:56 pm

- Location: Waikato, New Zealand

- Has thanked: 1 time

Re: Clutch travel & adjustment question again

A thin washer in behind the release bearing can do the same job as a bent arm or extended pushrod. Totally hidden.

- whistler

- 1275 Cooper S

- Posts: 830

- Joined: Sat Nov 05, 2016 5:02 pm

- Location: Cardiff

- Has thanked: 10 times

- Been thanked: 4 times

Re: Clutch travel & adjustment question again

I had a similar problem with my 1098 build. Cured it with an adjustable slave pushrod. I follow a lot of AC Dodd's posts on FB and it seems a lot of the new clutch diaphragms need setting up on the flywheels as regard the height of the 3 spacers and the back plate horns.

-

olddave

- 998 Cooper

- Posts: 601

- Joined: Sat Apr 09, 2016 4:23 pm

- Location: Yorkshire side of Bedfordshire

- Been thanked: 4 times

Re: Clutch travel & adjustment question again

I'm with Larry. A bent or worn bit on the lever below the pivot point.

-

AndyPen

- 1275 Cooper S

- Posts: 3841

- Joined: Mon Jul 24, 2017 5:55 pm

- Location: South Wales

- Been thanked: 22 times

Re: Clutch travel & adjustment question again

Both the lever and plunger are new but who knows? The pivot pin is tight and no ovaling in the hole, with a new pivot pin too. Something is out anyway!!

Re: Clutch travel & adjustment question again

Thought I'd chime in on this discussion...know we have covered this before.

However, here is what I have found and what I do to restore the setup to as close to original.

First, I have found as many as three different arms...4 if you count the after market 'fat' one.

These were matched to the end cover (wok)

mismatching will produce longer travel.

Next, bending the arm...longer pushrods...adjustable pushrods are just a way of compensating for the many issues that cause the long travel and low bite.

Here are some of the problems I have encountered.

Worn ball at the bottom of the arm

Clevis pins worn.

End cover pivot hole worn.

Worn thrust washers on the center main.

Incorrectly setup diaphragm and flywheel.

Worn tail on the crankshaft.

Leaky slave cylinder.

As peter mentioned....arm has 5:1 ratio...doesn't take must for a few thou here and there to be translated into a lot more at the slave cylinder.

You can weld the ball up and machine round again....that will help.

Replacing the clevis pins

Rebushing the end cover.

I aways put a thin washer behind the throw out bearing....

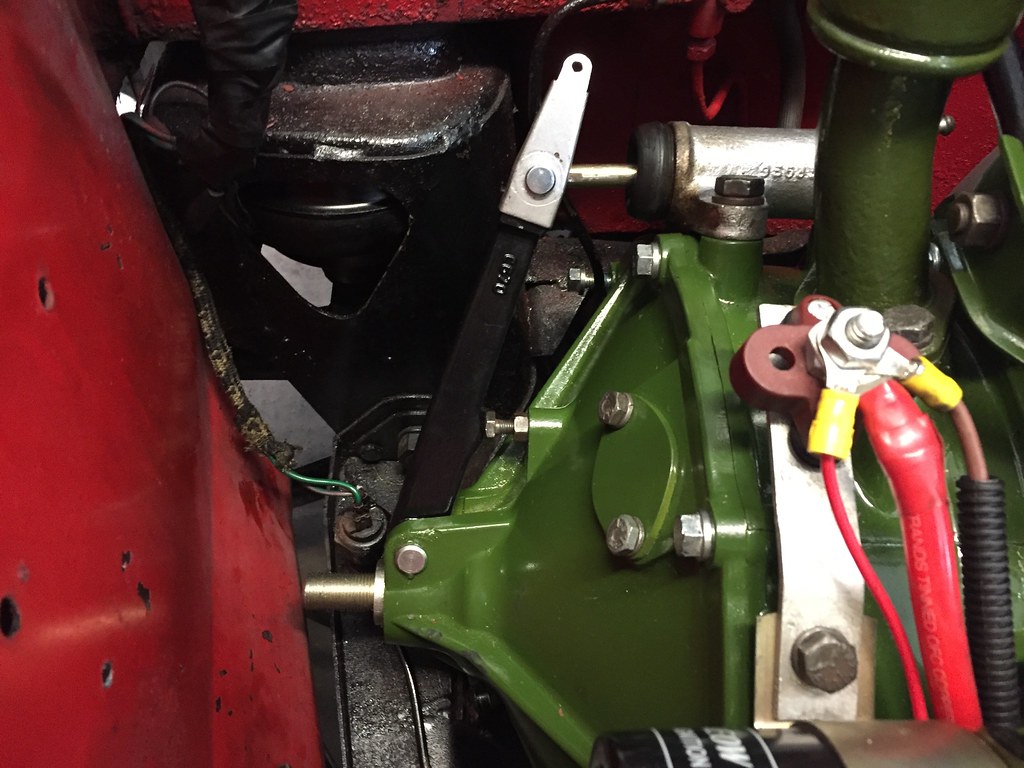

A correctly setup arm will lay almost parallel to the end cover....as you can see in this old picture.

However, here is what I have found and what I do to restore the setup to as close to original.

First, I have found as many as three different arms...4 if you count the after market 'fat' one.

These were matched to the end cover (wok)

mismatching will produce longer travel.

Next, bending the arm...longer pushrods...adjustable pushrods are just a way of compensating for the many issues that cause the long travel and low bite.

Here are some of the problems I have encountered.

Worn ball at the bottom of the arm

Clevis pins worn.

End cover pivot hole worn.

Worn thrust washers on the center main.

Incorrectly setup diaphragm and flywheel.

Worn tail on the crankshaft.

Leaky slave cylinder.

As peter mentioned....arm has 5:1 ratio...doesn't take must for a few thou here and there to be translated into a lot more at the slave cylinder.

You can weld the ball up and machine round again....that will help.

Replacing the clevis pins

Rebushing the end cover.

I aways put a thin washer behind the throw out bearing....

A correctly setup arm will lay almost parallel to the end cover....as you can see in this old picture.

You do not have the required permissions to view the files attached to this post.

-

AndyPen

- 1275 Cooper S

- Posts: 3841

- Joined: Mon Jul 24, 2017 5:55 pm

- Location: South Wales

- Been thanked: 22 times

Re: Clutch travel & adjustment question again

I think we may be back to the mismatching of new parts Dermot, and that visual clue of the arm angle is very helpful, not least that it brings into question why the adjustable pushrod is required at all?360gts wrote: ↑Sat Nov 16, 2024 6:42 pm Thought I'd chime in on this discussion...know we have covered this before.

However, here is what I have found and what I do to restore the setup to as close to original.

First, I have found as many as three different arms...4 if you count the after market 'fat' one.

These were matched to the end cover (wok)

mismatching will produce longer travel.

Next, bending the arm...longer pushrods...adjustable pushrods are just a way of compensating for the many issues that cause the long travel and low bite.

Here are some of the problems I have encountered.

Worn ball at the bottom of the arm

Clevis pins worn.

End cover pivot hole worn.

Worn thrust washers on the center main.

Incorrectly setup diaphragm and flywheel.

Worn tail on the crankshaft.

Leaky slave cylinder.

As peter mentioned....arm has 5:1 ratio...doesn't take must for a few thou here and there to be translated into a lot more at the slave cylinder.

You can weld the ball up and machine round again....that will help.

Replacing the clevis pins

Rebushing the end cover.

I aways put a thin washer behind the throw out bearing....

A correctly setup arm will lay almost parallel to the end cover....as you can see in this old picture.

The diaphragm on her car was new as you know, but I didn't mention that the pressure plate was tested for the three posts versus friction surface distance, as it was a new old stock steel one that I didn't quite trust - as is sometimes the case with NOS they can be defective returns.

I am also going to check the thrusts again - to see if I can detect movement at all. Fingers crossed that isn't the case eh?

This wasn't an issue prior to the new clutch parts being fitted mind you, and that only happened (not done by me unfortunately) because I had all the parts to hand. I know I kept the original narrow arm and plunger - so I wonder if I can find them for a direct comparison??

- timmy201

- 1275 Cooper S

- Posts: 1913

- Joined: Mon Jun 10, 2013 9:57 am

- Location: Australia

- Been thanked: 4 times

Re: Clutch travel & adjustment question again

There’s a good cutout view here. Ideally the throw out bearing will be as close as possible to the clutch diaphragm, then the slave cylinder will be close to the start of it’s travel. This gives a longer service life accounting for future wear

https://www.moke.com.au/in-the-garage/g ... the-clutch As mentioned above one good option is to put a washer on befor the throw out bearing. A few mm on the short side of the clutch arm makes a huge difference due to the leverage ratio (I also had a hardened sleeve pressed into the plunger so the arm would wear first as the arm is much easier to change

https://www.moke.com.au/in-the-garage/g ... the-clutch As mentioned above one good option is to put a washer on befor the throw out bearing. A few mm on the short side of the clutch arm makes a huge difference due to the leverage ratio (I also had a hardened sleeve pressed into the plunger so the arm would wear first as the arm is much easier to change

You do not have the required permissions to view the files attached to this post.

-

Aussie Bill B

- 850 Super

- Posts: 181

- Joined: Fri Dec 27, 2013 10:19 am

- Location: Camden NSW AUSTRALIA

Re: Clutch travel & adjustment question again

Timmy201's posted illustrations and cures suggest that a major issue for clutch adjustment may be caused by variations in the dimensions of the aftermarket parts.

Comments have been about the different clutch arms available and their various angles of the ball foot, below the pivot point.

Other discussions on Ausmini website have pointed out variations of hardness of the bearing carrier, away from original factory specifications.

But is the ball socket in the bearing carrier in the correct position? It would be interesting to see if there are any variations in the location of the ball socket measured from the throw-out bearing stop, between original carriers and any aftermarket examples.

If it is in the correct position, why the need for a spacer washer?

- Spider

- 1275 Cooper S

- Posts: 4775

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 59 times

- Been thanked: 15 times

Re: Clutch travel & adjustment question again

Machining of the backing plate posts to get the diaphragm spring dead flat is the single most cause of moving the diaphragm away from the bearing. Sire, thing like lapping the flywheel will too, but maybe by 1/2 a thou after working at a taper with lapping past for an hour.

- timmy201

- 1275 Cooper S

- Posts: 1913

- Joined: Mon Jun 10, 2013 9:57 am

- Location: Australia

- Been thanked: 4 times

Re: Clutch travel & adjustment question again

I would think there are so many potential spots for wear and/or aftermarket parts tolerances that sometimes you need to make allowances:

Crank thrust tolerances & thrust washers

The fit of the flywheel on the crank taper

The overall dimensions of the flywheel, pressure plate, washer

Material remaining on the clutch plate and how it was setup

Tolerance on the clutch cover pivot & clevis

Clutch arm, plunger & bearing tolerances

Length of the clutch pushrod and fit of the clevis

Of course fitting a longer pushrod will achieve the same result as adding the washer to the bearing, but you may come to a point where the clutch arm has run past it’s allowable angle

Crank thrust tolerances & thrust washers

The fit of the flywheel on the crank taper

The overall dimensions of the flywheel, pressure plate, washer

Material remaining on the clutch plate and how it was setup

Tolerance on the clutch cover pivot & clevis

Clutch arm, plunger & bearing tolerances

Length of the clutch pushrod and fit of the clevis

Of course fitting a longer pushrod will achieve the same result as adding the washer to the bearing, but you may come to a point where the clutch arm has run past it’s allowable angle

-

Polarsilver

- 1275 Cooper S

- Posts: 2803

- Joined: Fri Jan 15, 2016 12:22 pm

- Location: Silverstone not far away

- Has thanked: 3 times

- Been thanked: 17 times

Re: Clutch travel & adjustment question again

Just a thought .. have we all be sucked in that the aftermarket Thrust Bearing is the correct dimension given some of you are fitting a packing washer to make things work ..Or perhaps the aftermarket shaft that the Thrust Bearing Fits on is tolerance wrong as there is some odd reason to need a packing washer behind the bearing ?.. ( OK i can understand "Why" if you have "Moved" the Crank or Flywheel along a bit ) .. IF that is the current situation why do suppliers such as MS & the like..not supply as an option a backing washer with each Thrust Bearing they sell

Most Certain these "Modern" type Thrust Bearings that i have past fitted had a much shorter life than the ye-olde BMC Thrust Bearing that seemed to last forever, even it became a bit noisy & with evident side slop after decades of working with worn out crank thrust washers .. probably me wearing Rose Tinted Glasses these days

Most Certain these "Modern" type Thrust Bearings that i have past fitted had a much shorter life than the ye-olde BMC Thrust Bearing that seemed to last forever, even it became a bit noisy & with evident side slop after decades of working with worn out crank thrust washers .. probably me wearing Rose Tinted Glasses these days

- timmy201

- 1275 Cooper S

- Posts: 1913

- Joined: Mon Jun 10, 2013 9:57 am

- Location: Australia

- Been thanked: 4 times

Re: Clutch travel & adjustment question again

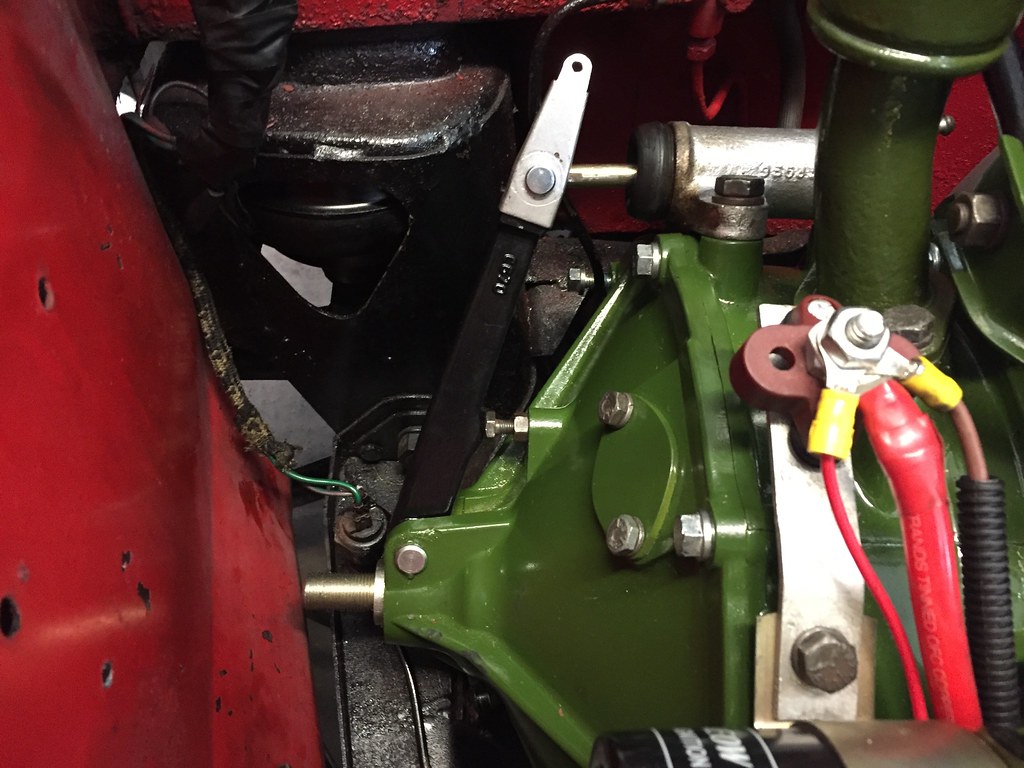

When I first put mine together (with used & working BMC original parts) the angle of the clutch arm was nearly 90 degrees to the axis of the plunger. It ran out of travel at the slave before it disengaged the clutch. Old stuff on the left and new on the right

After a round of new parts (and the washer) it’s much improved and has been working great for 5 years so far

After a round of new parts (and the washer) it’s much improved and has been working great for 5 years so far