Page 1 of 1

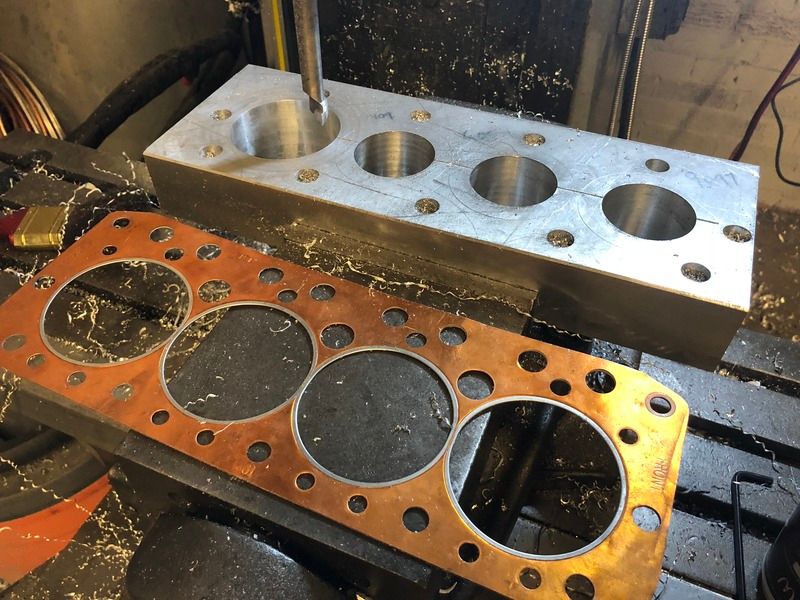

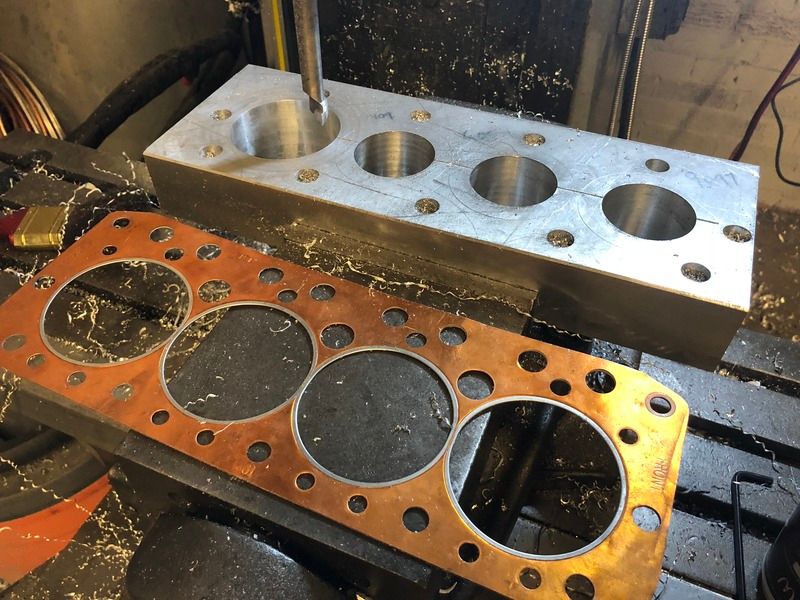

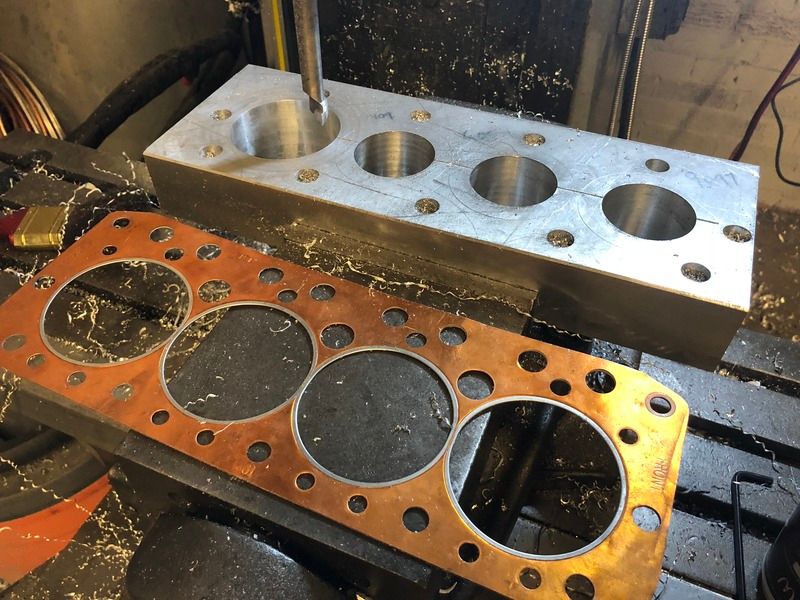

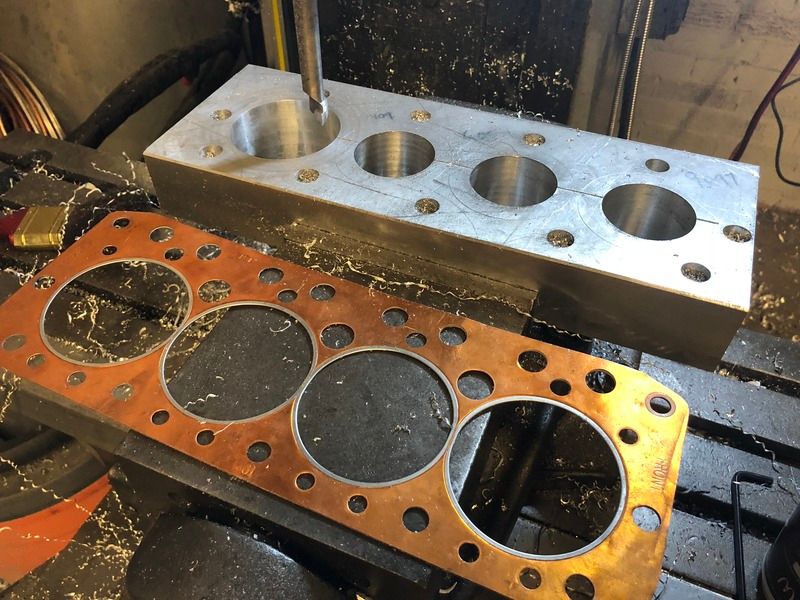

making my own honing plate

Posted: Mon Mar 05, 2018 7:10 pm

by Jim1071

Hi making my own honing plate

I will use while honing and checking ring gap

this plate gets bolted and torqued to the head using socket head cap screws and a head gasket

I am building a 1293 cc race motor for vintage racing

Re: making my own honing plate

Posted: Mon Mar 05, 2018 9:30 pm

by Beatie

Jim1071 wrote:Hi making my own honing plate

I will use while honing and checking ring gap

this plate gets bolted and torqued to the head using socket head cap screws and a head gasket

I am building a 1293 cc race motor for vintage racing

Is it just me or does everyone have a 1" paintbrush for wiping suds down the bore when boring

Re: making my own honing plate

Posted: Tue Mar 06, 2018 1:04 pm

by CooperTune

Many years ago while looking thought a sale flyer at the machine shop I noticed a close out sale of stress plates for A and B engines. I couldn't help but buy one for A series. I machined up a set of 1 inch dia. spacers so I could torque with ARP hardware. A little like working with a porcupine but I figured the course threads are not the ones doing the work as a rule.

For those really reaching out there we once set up a small hot water heater a pump and circulated 180 degree water though the blocks when machining.

You mention a 1071 for vintage, what group do you race with? Steve (CTR)

Sorry, I misread your 1293, wishful thinking.

Re: making my own honing plate

Posted: Wed Mar 07, 2018 2:37 am

by atm92484

Nice work Jim. I made one from steel plate a few years ago.

Re: making my own honing plate

Posted: Wed Mar 07, 2018 1:01 pm

by Jim1071

CooperTune wrote:

For those really reaching out there we once set up a small hot water heater a pump and circulated 180 degree water though the blocks when machining.

You mention a 1071 for vintage, what group do you race with? Steve (CTR)

Sorry, I misread your 1293, wishful thinking.

I never thought of heating the block

my 1071 is restored 1964

Re: making my own honing plate

Posted: Wed Mar 07, 2018 1:02 pm

by Jim1071

atm92484 wrote:Nice work Jim. I made one from steel plate a few years ago.

thank you

did yours work out ok

I could not believe that a cylinder block gets deformed once head is on

Re: making my own honing plate

Posted: Sun Mar 11, 2018 2:00 am

by atm92484

Yeah it worked nicely. The engine did a season and a half before receiving new rings and bearings just in time for the last race of 2017 in which it ran very well. I am not sure how much our blocks move but it seems like minimal effort to make/buy one and do it right.

I used 3/4" thick plate for mine so I also bought some thick wall tube with an ID a hair over 3/8" - I cut them to length and squared them on a friend's lathe so the studs could be used instead of shorter bolts.

I did not have a mill at the time. A 2.75" holesaw leaves a hole that is a hair over 2.82" - perfect for +0.040" on a 1275. The rest was down to careful measuring and transferring holes from the head.

Re: making my own honing plate

Posted: Sat Mar 17, 2018 11:54 pm

by Jim1071

finally finished the honing boring plate

ready for the engine installation assembly

Re: making my own honing plate

Posted: Sat Mar 17, 2018 11:56 pm

by Jim1071

atm92484 wrote:

I did not have a mill at the time. A 2.75" holesaw leaves a hole that is a hair over 2.82" - perfect for +0.040" on a 1275. The rest was down to careful measuring and transferring holes from the head.

I was thinking of hole saw ,,,, but I used a 2 inch thick plate

Re: making my own honing plate

Posted: Sun Mar 18, 2018 12:10 pm

by jerry

Could the plates be CNC laser or plasma cut to size? I wonder what the cost would be??

Jerry

Re: making my own honing plate

Posted: Sun Mar 18, 2018 12:16 pm

by Peter Laidler

Cost.....? Not a lot I'd say if they were waterjet cut especially if you did a few and sold them on to recoup your original cost

Re: making my own honing plate

Posted: Mon Mar 19, 2018 12:05 pm

by Jim1071

jerry wrote:Could the plates be CNC laser or plasma cut to size? I wonder what the cost would be??

Jerry

the price would be expensive if you only have one plate

the aluminum cost me 80 dollars ( approx. 50 pounds uk )

then I used the digital read out X,Y,Z, , which saved time ON the second one

the first I tried the old fashion way and was out ...

I saw hone plates as high as 450 usa dollars but not Austin mini

I enjoyed making it

now I can start putting back the race motor