Oil gallery Threaded hex grub screws

-

rolesyboy

- 1275 Cooper S

- Posts: 2370

- Joined: Fri Jun 25, 2010 10:57 am

- Location: Colchester, Essex

- Has thanked: 19 times

- Been thanked: 9 times

Oil gallery Threaded hex grub screws

Would M14 grub screws so the trick for oil galleries on an S block? Does anybody happen to have a link to the right sort ie not so long that they would block a gallery?

Thanks. Mark

Thanks. Mark

Rolesyboy

- Spider

- 1275 Cooper S

- Posts: 4863

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 206 times

- Been thanked: 80 times

Re: Oil gallery Threaded hex grub screws

For the Main Oil Gallery, M14 is what I use.

When tapping the holes, be careful not to tap them too deep or you can reduce or even cut off the Oil Flow to No. 1 and No. 3 Main Bearings. Have a look in the Gallery and you'll see what I'm banging on about. I like to start off the Tapping in the Drill Press (switched OFF, turned by hand) just to be absolutely sure of getting the threads square. I use the Cup Point type Grub Screws, not the Knurled types and I Tap the Gallery such that the Cup seats in the bottom of the original plug drilling. Clean, clean again with Thinner, Loctite and Screw away. They don't need to be fitted mega tight, just tight enough to seat.

When tapping the holes, be careful not to tap them too deep or you can reduce or even cut off the Oil Flow to No. 1 and No. 3 Main Bearings. Have a look in the Gallery and you'll see what I'm banging on about. I like to start off the Tapping in the Drill Press (switched OFF, turned by hand) just to be absolutely sure of getting the threads square. I use the Cup Point type Grub Screws, not the Knurled types and I Tap the Gallery such that the Cup seats in the bottom of the original plug drilling. Clean, clean again with Thinner, Loctite and Screw away. They don't need to be fitted mega tight, just tight enough to seat.

-

rolesyboy

- 1275 Cooper S

- Posts: 2370

- Joined: Fri Jun 25, 2010 10:57 am

- Location: Colchester, Essex

- Has thanked: 19 times

- Been thanked: 9 times

Re: Oil gallery Threaded hex grub screws

Thanks Spider. Any links for somebody who sells the right item or specs for what i need? TPI, length, material ??

I cant seem to source any locally

Cheers

I cant seem to source any locally

Cheers

Rolesyboy

- Spider

- 1275 Cooper S

- Posts: 4863

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 206 times

- Been thanked: 80 times

Re: Oil gallery Threaded hex grub screws

The ones I use are fairly common, M14 x 2.0 mm.

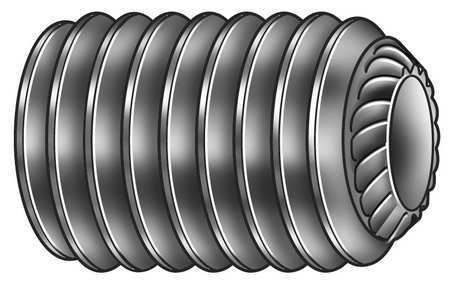

Use Cup Points, which look like this

DON'T try these on (knurl point);-

Near to you there are a few place that should be able to supply;-

https://plus.google.com/113247910862721 ... bout?hl=en

http://suffolkfastener.co.uk/home/2310918

http://www.southessexfasteners.com/home

http://powerfix-colchester.co.uk/

Use Cup Points, which look like this

DON'T try these on (knurl point);-

Near to you there are a few place that should be able to supply;-

https://plus.google.com/113247910862721 ... bout?hl=en

http://suffolkfastener.co.uk/home/2310918

http://www.southessexfasteners.com/home

http://powerfix-colchester.co.uk/

-

mk1

- Site Admin

- Posts: 19835

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 3 times

- Been thanked: 10 times

Re: Oil gallery Threaded hex grub screws

Couple of questions.

Questions 1.

Why shouldn't you use knurl point? They are not driving into anything so what difference does it make?

Question 2.

Why not just use standard gallery plugs in the big gallery? The plugs are widely available & work fine. I do tap & grub screw the small galleries but just punch the plugs out & replace on the large gallery, Easy.

Questions 1.

Why shouldn't you use knurl point? They are not driving into anything so what difference does it make?

Question 2.

Why not just use standard gallery plugs in the big gallery? The plugs are widely available & work fine. I do tap & grub screw the small galleries but just punch the plugs out & replace on the large gallery, Easy.

- 850man

- 998 Cooper

- Posts: 360

- Joined: Fri Nov 09, 2012 11:08 am

- Location: Melbourne, Australia.

Re: Oil gallery Threaded hex grub screws

The knurl point grub screws cut into the seat and create swaff. not want you want in your freshly cleaned oil gallery.

No reason why you cant use the normal replacement plugs. The grub screws are used of performance engines that get rebuilt on a regular basis, either because something has exploded or just a freshen up. It is easier to remove the grub screw than have to drill out a plug.

No reason why you cant use the normal replacement plugs. The grub screws are used of performance engines that get rebuilt on a regular basis, either because something has exploded or just a freshen up. It is easier to remove the grub screw than have to drill out a plug.

Restoration Specialist - https://www.facebook.com/linkautomotive

- Spider

- 1275 Cooper S

- Posts: 4863

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 206 times

- Been thanked: 80 times

Re: Oil gallery Threaded hex grub screws

With the Cup Points, they'll seal (if done right) two ways, on the Cup and on the Thread, so you have a back up. Also, as the guy ^^ with tetnus says (potential for swarf).mk1 wrote:Couple of questions.

Questions 1.

Why shouldn't you use knurl point? They are not driving into anything so what difference does it make?

IMO, a number of reasons. There is a risk when re-fitting stock solid type plugs of shaving, which may leave swarf where you don't want it and also a leak (seen this more than once). The later pressed type plugs seem far less prone to this and I'm guessing this may have been a factor in the factory going this way.mk1 wrote:

Question 2.

Why not just use standard gallery plugs in the big gallery? The plugs are widely available & work fine. I do tap & grub screw the small galleries but just punch the plugs out & replace on the large gallery, Easy.

If the bore from the original drilling isn't 'clean' (un-marked), they can leak.

Pressed in plugs should also be 'staked' following fitting to ensure they don't come out. There's only so many times this can be done and it makes getting the plugs out at overhaul time that much more messy and when cleaning up the drillings of these stakings, it can lead to the point above.

Obviously the removable plug does make it very easy to remove them at an overhaul, 20 seconds vs 2 minutes. Remember - I am a lazy sod!

If after fitting, they are found to leak (heaven forbid!), screwed plugs are very simple to rectify, punched plugs are not so easy.

I think the screwed plugs are on a par as far as cost goes, but regardless - either way, we're talking peanuts.

I really can't remember when I last fitted a punch plug, well over 25 years ago.

-

mk1

- Site Admin

- Posts: 19835

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 3 times

- Been thanked: 10 times

Re: Oil gallery Threaded hex grub screws

If you look at a knurl point grub screw the knurl is inside the ID of the thread. So it can't create any swarf in a straight oil gallery as the knurl never touches anything. the knurls are on there to allow them to cut into drive shafts etc. When the grub screws are used to secure pulleys.

You do not have the required permissions to view the files attached to this post.

-

mk1

- Site Admin

- Posts: 19835

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 3 times

- Been thanked: 10 times

Re: Oil gallery Threaded hex grub screws

Fair points made re the big gallery plug. But i have never had any bother with the tin type despite changing them regularly in race engines. I always fit them with araldite though.

M

M

- Spider

- 1275 Cooper S

- Posts: 4863

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 206 times

- Been thanked: 80 times

Re: Oil gallery Threaded hex grub screws

Yes, that's true where the knurling is, however the drilling in the blocks are 5/8" dia where the plug goes, and then very soon after reduces to a tad over 5/16". I tap the blocks such that the Cup seats on the step where the Gallery reduces in dia, which is roughly were the Knurl would also seat (and possibly rip bits off). I have a sketch somewhere, I'll post up.mk1 wrote:If you look at a knurl point grub screw the knurl is inside the ID of the thread. So it can't create any swarf in a straight oil gallery as the knurl never touches anything. the knurls are on there to allow them to cut into drive shafts etc. When the grub screws are used to secure pulleys.

I've never used Araldite on plugs, not a bad idea, though I do use Loctite on all plugs, not so much to lock them but to seal them.

-

mk1

- Site Admin

- Posts: 19835

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 3 times

- Been thanked: 10 times

Re: Oil gallery Threaded hex grub screws

Fair point again. I was only really referring to gallery plugs used for the small drillings as, as I have already said I have never bothered using threaded plugs on the big oil way.

M

M

- Spider

- 1275 Cooper S

- Posts: 4863

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 206 times

- Been thanked: 80 times

Re: Oil gallery Threaded hex grub screws

Sorry Mark - Rolesy did seem to be banging on about the Main Oil Gallery (re M14 Plugs), but yes, on the smaller plugs found in the front of the block and in the head, you are right, it wouldn't matter what style of threaded plug was used, it's just that the knurled ones also look a bit angry!

Those smaller plugs you can only get to seal on the threads and I've had no problems in achieving that, though, one could drill them to make a seat,,,,,,,

Those smaller plugs you can only get to seal on the threads and I've had no problems in achieving that, though, one could drill them to make a seat,,,,,,,