Page 1 of 1

Re-bushing a rod change housing

Posted: Tue Jan 06, 2015 8:21 pm

by tomkidd

Hi folks

After the last track day my gearbox decided it would start to play up after wacking it into 2nd for the chicane a few to many times...

For the rebuild I want to make sure its all mint. If I am going to rebush the housing for the gear linkage (stick end) what parts do I need and how hard is it to do?

Cheers

Re: Re-bushing a rod change housing

Posted: Tue Jan 06, 2015 9:42 pm

by Dr S

Hi tom,

When mine went slack it was the make female coupling on the back of the box that where moving about. Managed to get one part nos and one good secondhand. Visibly less play on the back of the box now.

Haven't driven it yet mind. Think you can buy the long fork for the inside of the remote but mine felt ok with a waggle after changing the knuckle.

Nick

Re: Re-bushing a rod change housing

Posted: Tue Jan 06, 2015 9:51 pm

by tomkidd

Thanks Nick but I am not quite sure what you are trying to explain! Sorry!

Re: Re-bushing a rod change housing

Posted: Tue Jan 06, 2015 10:01 pm

by Dr S

Ok, the remote connects to the back of the box, the linkage then exits the top of the diff housing and changes direction via a knuckle joint. This was the problem on my box. Not the remote.

Re: Re-bushing a rod change housing

Posted: Tue Jan 06, 2015 10:03 pm

by GraemeC

Tom's got a rod change, not a remote change, though

Re: Re-bushing a rod change housing

Posted: Tue Jan 06, 2015 10:04 pm

by Dr S

Ah...

Re: Re-bushing a rod change housing

Posted: Wed Jan 07, 2015 3:48 am

by minibitz

I drive the bushes out of the housing and fit new ones. The rod often wears where it enters the hosing & bush. Usually you can swap the rod around as the end connecting to the shaft coming out of the diff has less wear. The gear lever also wears badly. Check the nylon ball at the end and also the slot that locates the lever into the housing. Replace lever if worn. Also check the metal/rubber bush for the stabiliser bar that is located on the rear of the diff housing.

Re: Re-bushing a rod change housing

Posted: Wed Jan 07, 2015 7:11 am

by Spider

I've done a few now. The Bushes are what are known as a DU Bush, the ones in the shifter are Catalogue Number R-08DU08. They are 1/2" ID x 0.600" OD x 1/2" Long. Try an Industrial bearing Supplier for these, should only be a couple of bucks each. I turned up a punch which is stepped being 0.495" on the smaller dia and 0.592" Dia on the Major Dia for getting the old ones out and the new ones in.

The Rod Shift set up seems to come in for a lot of crititism compared to the Remote Shift. I have both across a few of my cars and while the Remote does have a more 'notchy' feel when actually going in to and out of Gear, when all the parts are overhauled on a Rod Shift, in my opinion, they do actually feel better than a Remote, only they can wear faster, however 99% of that wear comes from dirt, so keeping them clean goes a long way to keeping them good for longer. I've also fitted a few additional covers (and still working on a few others) to stop the dirt getting in to them in the first place.

Re: Re-bushing a rod change housing

Posted: Wed Jan 07, 2015 7:36 am

by tomkidd

Cheers for the replies folks.

Guru if you are reading this can you supply new bushes?

I am actually running a KAD internal linkage kit so the main rod to the box is new and the stick is new. The linkage box was (I thought so anyway) in decent condition.

Re: Re-bushing a rod change housing

Posted: Fri Jan 09, 2015 11:05 am

by LuisM

Hi,

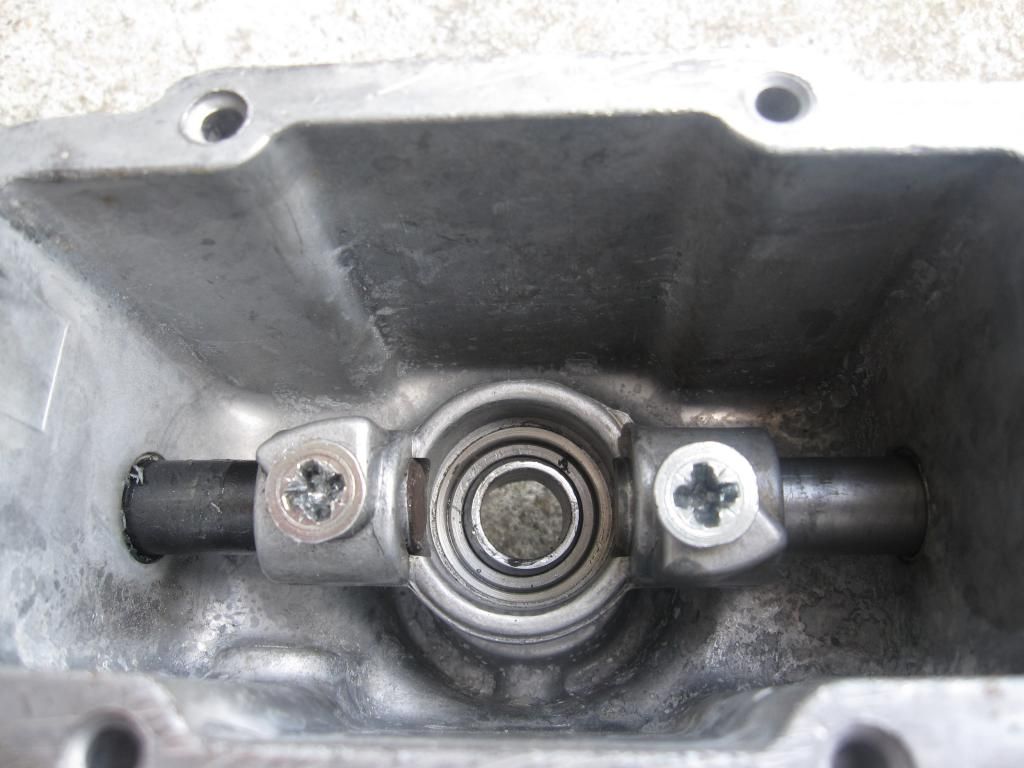

i'm not sure if you will find bushes off the shelf, never seen them. You can have bronze or nylon bushes made as below .

Ask the machinist to ream the front and rear bush inline.. or the whole thing may become tight.

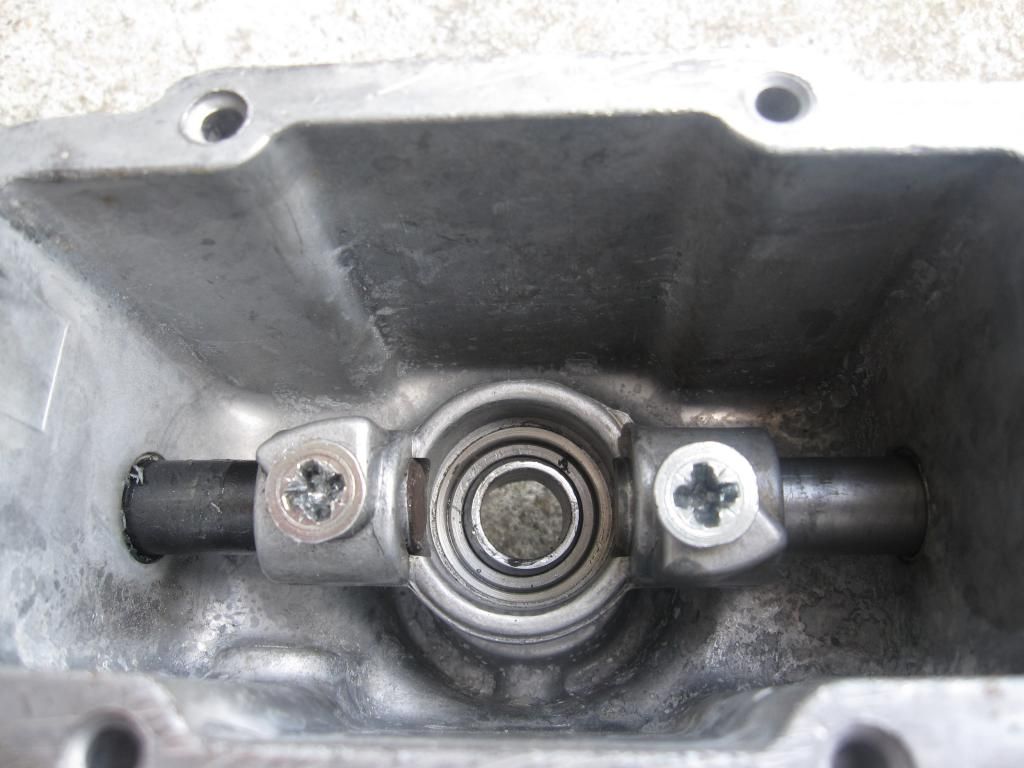

Something nice to do is to get rid of the sloppy eye rod/ball, using a spherical bearing inside the eye rod ( ref GE12C suits well ) , you just need to machine/slim down a bit the gearstick end.

Cheers

Luis

Re: Re-bushing a rod change housing

Posted: Fri Jan 09, 2015 12:03 pm

by rich@minispares.com

luis

that's a neat bit of work there!!

Re: Re-bushing a rod change housing

Posted: Fri Jan 09, 2015 1:50 pm

by CooperTune

Up to around 2000 I had never seen a rod change shifter. While building US vintage racers I began using them located in the cabin. Last year maybe the year before I rebuilt 10 units. The problem I'm running into is the front bushing wearing out and the shift rod cutting into the housing. I bought a .625 reamer and machined some little bushing to align it. I ream the housing to .625 each end. McMaster Carr supplies .625 X .500 X .500 bushings. I press these in place and run a .500 ream though to insure alignment. When possible I flip the shift rod as mentioned. If not I cut a new length of cold roll. As for the shift eyes. When they went down in price I bought a bag full, now they seem to have gone back up. I have also set them up and bored them to 1.125 and press in a sleeve 1.125 X .875 and reuse. The front of the housing accepts a 1 X .500 X .250 grease seal which stops dirt and water from entering. Got the idea from the Inno sealed ones. Some Innos also have the chrome sticks and a plastic bushing where the small ball fits the shift eye.

I had been buying cheap MSC quick shift kits setting the stick up and recutting the snap ring grooves moving the ball up and cutting the shaft off to make a std stick that's chrome.

I had two complete shift unit show up this week and they are stripped and cleaned. I will ream and rebush today and send them home monday. I either glass bead and paint the parts or send out for cad plating if the customer wants to pay the extra charge for that. I like the bearing in the shift eye idea. I will look though the progressive size chart for something that will work. Steve (CTR)

Re: Re-bushing a rod change housing

Posted: Fri Jan 09, 2015 3:30 pm

by LuisM

luis

that's a neat bit of work there!!

Thanks Rich, the 1st housing photo is not mine.. but i had one of mines bushed similar.

The one with the eye ball bearing is one of my housings, i took the chance and replaced the roll pins by S/GT rear brake drum screws. ( i broke an eye rod removing the pins ) .

The bearing ref GE12C is 12mm internal diameter x 22mm external , another good thing is that you can locate the bearing a bit lower in the eye rod having a lower "pivot point" and gain a bit of "quick shift" effect.

Cheers

Luis

Re: Re-bushing a rod change housing

Posted: Fri Jan 09, 2015 4:15 pm

by mk1

Very nice mods Luis.

Re: Re-bushing a rod change housing

Posted: Thu Jan 15, 2015 2:26 pm

by CooperTune

Thanks for posting that idea. I went on McMaster Carr and ordered a coupe of bearings 1 X 1/2 X 1/2 machined the eye for .003 press and left a 1/16 shoulder for it to sit on. First assembled and test / bench shifted and it's fine. The lower part of stick is 1/2 inch dia. after pressing the small ball off shaft there are small indents under ball to secure ball once in place. These have to be polished off to allow shaft though bearing. Having replaced 10/12 shift eyes I have plenty worn ones as well as ones people have broken. I will get them welded and see what I can do with them. Once I have a batch done I will offer them exchange. I'm also installing new bushing in the shift housings. Steve (CTR)

Re: Re-bushing a rod change housing

Posted: Fri Jan 16, 2015 2:47 pm

by LuisM

Nice that you find it helpful Steve,

something i forgot to mention but you got it right

as you left a bottom shoulder for the bearing to sit on.

Because the bearings i had were smaller diameter i 've used a steel sleeve with a shoulder at the bottom... the bearing sits inside the sleeve loctited, and then the sleeve is press fitted/loctited onto the shift eye.

Cheers

Luis

Re: Re-bushing a rod change housing

Posted: Mon Jan 19, 2015 3:42 pm

by CooperTune

I have to admit I liked the bearing idea so much I looked thought the Mc Master Carr book and came up with a bearing that's .500 X 1.0. I machined the eye to carry .003 press and left a 1/16 shoulder at the bottom to secure the bearing. I pressed the small ball off the stick to reveal small indents under the ball to help secure the ball. Once these are ground and polished off the stick slips though the bearing smoothly. I have found in doing these that often the rods have worn though the bushings and into the housing leaving a not round hole. Making up guides and buying a .625 and a .500 inch reamer I install .626 X .500 X .625 bushings The front one is a shouldered bush and the rear a std bush. I also install a 1 X .500 X .250 grease seal in the front of the housing to stop water and dirt from entering the forward bush. I currently have a thread running on Mini Mania board with pictures. Steve (CTR)