Page 2 of 16

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:17 pm

by Callum

Got the step fully welded at the weekend then started on the repair to the bottom of the quarter, got it tacked in tonight.

[/URL]

[/URL]

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:18 pm

by InimiaD

Fair play to you. That's a major restoration you have going on there and considering it's your first attempt the results so far look excellent.

Regarding the boot floor being a tight fit, I read somewhere that the boot floor pressings were made 10 mm wider between the wheel arches. Sometime in the late 70's early 80's.

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:19 pm

by Callum

Got it fully welded tonight, very pleased with how it came out thought there might be a lot of distortion.

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:20 pm

by Callum

Got the other side tacked in tonight

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:21 pm

by Callum

Finished welding the drivers side at the weekend, still need to linish it fully

Took it back off the spit again so I can get inside to finish welding the floor and arches, and ready for the front

bulkhead repairs. Finally got rid of the horrible bracing too

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:22 pm

by Callum

Finished spot welding the heel board to the boot floor on Saturday. Waiting for my angle die grinder to arrive

before I can finish cleaning to welds at the rear so I started on the front bulkhead. There is heavy pitting on most

of it so would need a lot of different patches making for it to be good again. I don't think I could make a good job

of it so I'm going to replace the whole thing with another one that I have. Cutting it down to just the part I need...

Still needs a bit more work and then sand blasting, don't know if I will do it myself or pay someone else to do it,

I hate sand blasting!

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:24 pm

by Callum

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:26 pm

by Callum

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:27 pm

by Callum

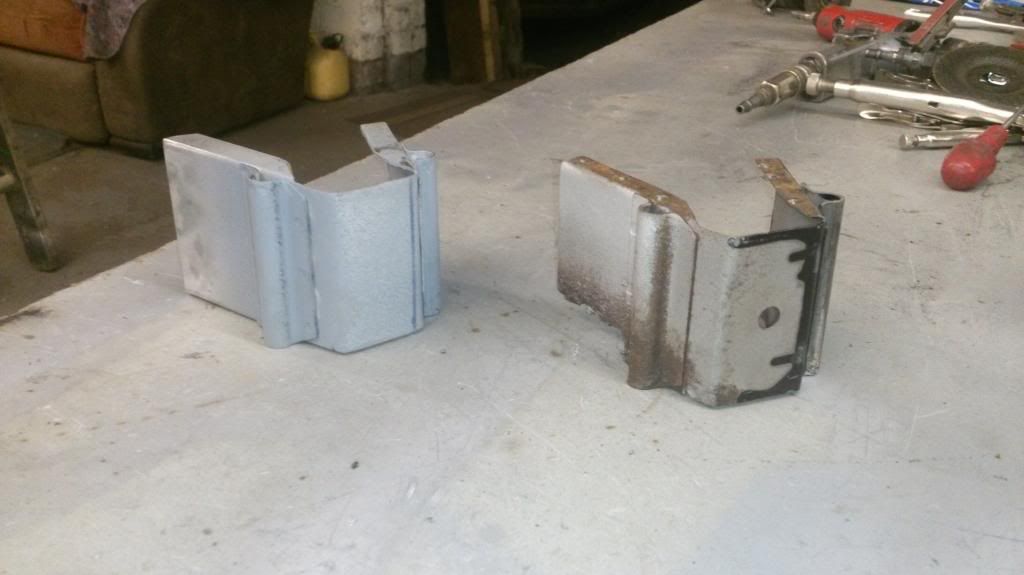

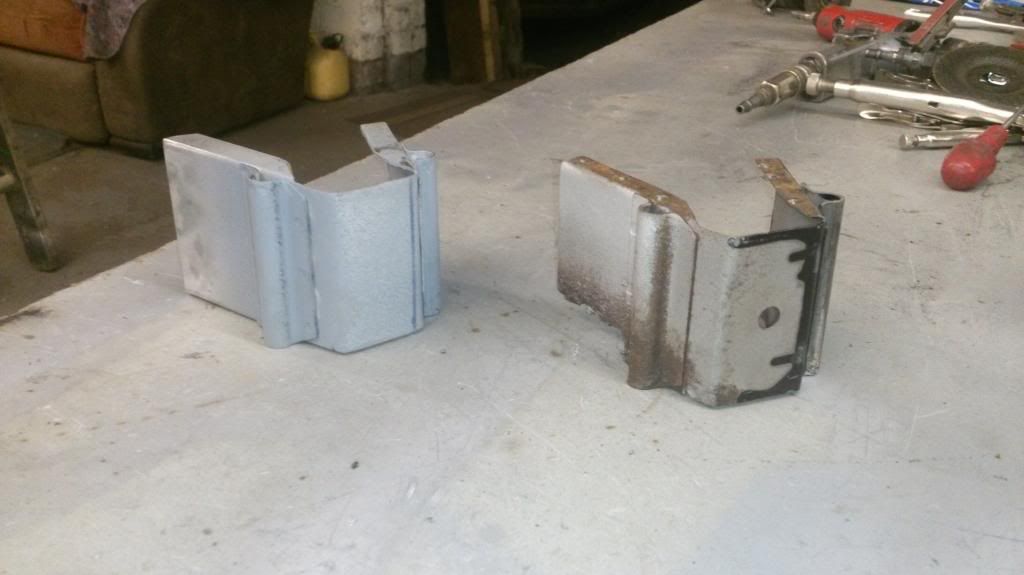

Had some more panels delivered last week. Been working on the toeboard panel over the weekend, you can only

buy the late type ones and the early ones are slightly different so been making some changes to it, still some more to do

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:28 pm

by Callum

Got the toe board finished yesterday, I made the subframe strengthening plates a bit bigger and out of thicker steel

than they are originally, don't no if that was needed but the original ones don't seem that substantial

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:29 pm

by Callum

Got a few spot welds on the toeboard tonight, it lines up with the jig so nothing has moved. Will finish welding it in

and then start repairing the bulkhead

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:30 pm

by Callum

Been working on the bulkhead for the past couple of weeks, there hasn't really been anything update worthy until

tonight. Welded a plate in at the end where it joins the toeboard/inner wing, forgot to take a picture of it before, needs finishing off when the cross member repairs are finished

Then started on the bottom of the cross member

Before

Repair made up and tacked in

Fully welded, blew a couple of holes along the top might of been a bit thin but probably just down to me still

learning to weld

Linished, got to add the holes for the subframe bolt and hydrolastic pipe

Made a new strengthener for where the subframe bolts pass through the cross member

Repaired one corner where it joins the windscreen scuttle

Thats it for now, cheers

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:31 pm

by Callum

Finished repairing the bulkhead over the bank holiday forgot to take pictures though. Got it welded to the toeboard tonight

Took the skins off the doors over the weekend and they are worse than I thought, the window surround needs

splitting from the rest of the door frame really so I'm going to try and find another pair before attempting to repair

these ones. Some pictures showing the rot

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:32 pm

by Callum

Had planned on keeping the original upper dash rail but it was quite pitted along the windscreen seam so went for

a new one. The new panel is made for a late mini, I didn't know but the heater vents are further apart on the older

ones so yet more cutting and welding new panels

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:33 pm

by Callum

Got the upper dash rail welded in last week as well as the inner sill closing panels on both sides

Finally found some doors so went to pick them up on sunday. They are very good and still have their original skins

which wont need any repairs , came off an early 60's racer and have supposedly never been on the road.

The drivers side is a good fit with an even gap most of the way round but the passenger side isn't so good. The back

edge of the skin touches the B pillar whilst the window frame is too far away. The pictures don't show it very well...

Not really sure what to do with that, is it a case of grinding the door skin lip back and then running a weld up it and keep going until there is an even gap? Cheers

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:34 pm

by Callum

Been working on the drivers side A panel tonight, its cut down and fits now so hopefully can weld it in tomorrow.

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:34 pm

by Callum

Got the A panel welded yesterday, got to turn it around and do the other side now

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:35 pm

by Callum

Got the A panel welded yesterday, got to turn it around and do the other side now

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:36 pm

by Callum

Not been able to do much just recently, I was working on the front but still need to buy the drivers side inner wing

and the scuttle before I can test fit all the panels and carry on welding. But I can't buy the panels as i'm very short

of spare cash at the moment, me and the misses are going through the process of buying our first house :-/

So I can only work with the panels I already have.

Got the companion bins welded in and that's pretty much all I have done. I probably wont have as much spare time either now so work on it will slow down. I wont sell it though!

Re: Mk2 Cooper

Posted: Sun Sep 28, 2014 9:38 pm

by Callum

Not much to update as I'm still working with the bits I have already got. Last month I welded the boot board brackets

in as well as the subframe strengthener things.

This month been working on the rear valance, decided to weld the closing panels to the valance first so I can paint

and seam seal inside before it gets closed off.

Cheers

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]