Been working on the bulkhead for the past couple of weeks, there hasn't really been anything update worthy until

tonight. Welded a plate in at the end where it joins the toeboard/inner wing, forgot to take a picture of it before, needs finishing off when the cross member repairs are finished

Then started on the bottom of the cross member

Before

Repair made up and tacked in

Fully welded, blew a couple of holes along the top might of been a bit thin but probably just down to me still

learning to weld

Linished, got to add the holes for the subframe bolt and hydrolastic pipe

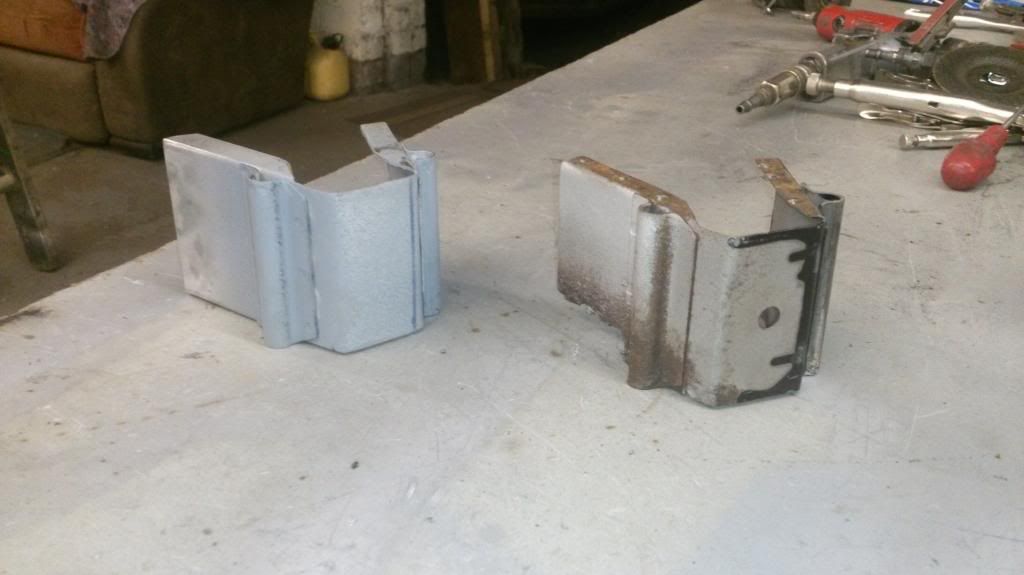

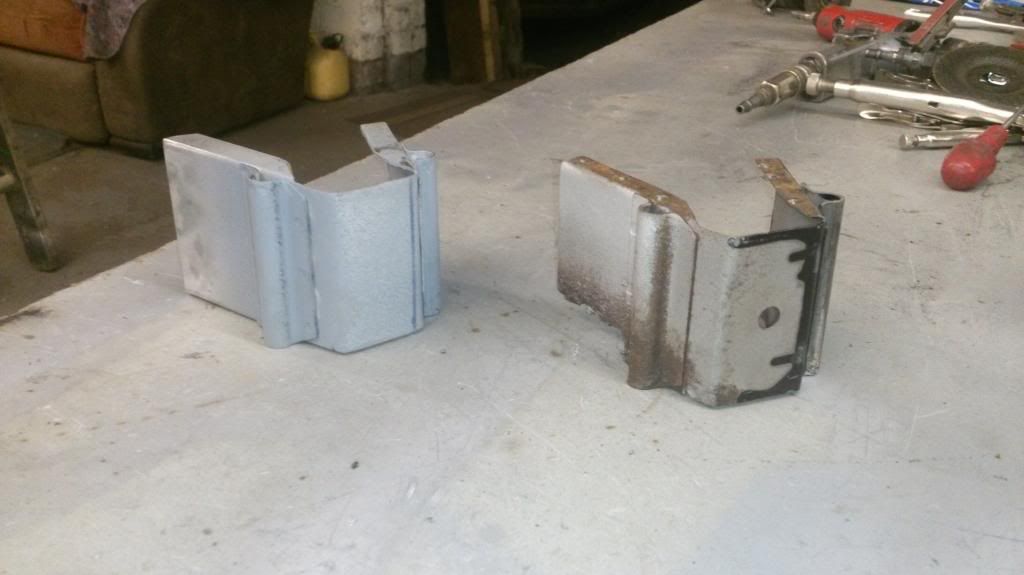

Made a new strengthener for where the subframe bolts pass through the cross member

Repaired one corner where it joins the windscreen scuttle

Thats it for now, cheers

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]