what's best way to clean up aluminum parts?

-

Chalkie

what's best way to clean up aluminum parts?

As title says need to clean aluminium parts eg carbs want that fresh factory look on them

Any good cleaning stuff out there?

Don't want a use a wire brush thanks

Any good cleaning stuff out there?

Don't want a use a wire brush thanks

-

mk1

- Site Admin

- Posts: 19843

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 2 times

- Been thanked: 5 times

Re: what's best way to clean up aluminum parts?

For parts like Carbs you have 2 real options, the easy one & the hard one.

Easy. Get a small Soda Blaster, blasting with crystalised sodium bicarbonate is absolutely superb & easy.

Difficult. Buy 25 litres of Cellulose thinners & get scrubbing. Not quite a "factory fresh" but excellent results none the less.

Easy. Get a small Soda Blaster, blasting with crystalised sodium bicarbonate is absolutely superb & easy.

Difficult. Buy 25 litres of Cellulose thinners & get scrubbing. Not quite a "factory fresh" but excellent results none the less.

-

Charlynsane

- 1275 Cooper S

- Posts: 1175

- Joined: Wed Jan 16, 2013 9:50 am

- Location: France

Re: what's best way to clean up aluminum parts?

As for me the best way to clean aluminium without damaging it is the nutshell blasting!

I did it on my carbs, it looks like a brand new carb, and you don't feel alumininium grinded on the top, like with classic sand blasting

I did it on my carbs, it looks like a brand new carb, and you don't feel alumininium grinded on the top, like with classic sand blasting

- Dr.Mabo

- 998 Cooper

- Posts: 500

- Joined: Wed Jun 27, 2012 1:05 pm

- Location: Germany

- Been thanked: 6 times

Re: what's best way to clean up aluminum parts?

I'm very satisfied with an Aluminum cleaner from the German company AMMON. The cleaner is called "AL80". The price is 19€/kg.

Its some kind of salt which needs to be mixed up with water. You have to heat up the mixture to 50-80°C. After about an hour the aluminum parts are totally clean, free of corrosion and brightened up as they left the factory.

Unfortunatly the discription and homepage is only in German language. But maybe it can help you somehow.

http://www.horex-ammon.de/product_info. ... niger.html

If its of any help, I have some before and after pictures, which I can post on request.

so long

the Doc

Its some kind of salt which needs to be mixed up with water. You have to heat up the mixture to 50-80°C. After about an hour the aluminum parts are totally clean, free of corrosion and brightened up as they left the factory.

Unfortunatly the discription and homepage is only in German language. But maybe it can help you somehow.

http://www.horex-ammon.de/product_info. ... niger.html

If its of any help, I have some before and after pictures, which I can post on request.

so long

the Doc

-

bpirie1000

- 998 Cooper

- Posts: 274

- Joined: Thu Jun 24, 2010 9:17 pm

Re: what's best way to clean up aluminum parts?

Auto sol and elbow grease fine wet and dry paper...

Maybe I am a sucker for punishment

Maybe I am a sucker for punishment

-

miniman24

- 850 Super

- Posts: 124

- Joined: Sun Jun 01, 2014 7:21 pm

Re: what's best way to clean up aluminum parts?

These inlets, ram stacks and rocker cover were cleaned by vapour blasting - nice finish to them.

[/url]

[/url]

[/url]

[/url]-

mk1

- Site Admin

- Posts: 19843

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 2 times

- Been thanked: 5 times

Re: what's best way to clean up aluminum parts?

Miniman24,

Are those stub stacks solid or spun?

Speedwell ones should be solid & chrome plated.

Like this;

Are those stub stacks solid or spun?

Speedwell ones should be solid & chrome plated.

Like this;

-

miniman24

- 850 Super

- Posts: 124

- Joined: Sun Jun 01, 2014 7:21 pm

Re: what's best way to clean up aluminum parts?

They are the later spun ones, still Speedwell I think, just not as desirable.

-

mk1

- Site Admin

- Posts: 19843

- Joined: Thu Jun 24, 2010 11:30 am

- Location: Away with the Faries

- Has thanked: 2 times

- Been thanked: 5 times

Re: what's best way to clean up aluminum parts?

have you seen the late catalogue off the main site, lots of stuff listed in there.

http://mk1-performance-conversions.co.uk/pdf/spd_70.pdf

M

http://mk1-performance-conversions.co.uk/pdf/spd_70.pdf

M

-

minitravellerman

- 1275 Cooper S

- Posts: 1040

- Joined: Fri Oct 08, 2010 3:57 pm

- Location: Banbridge, Co Down, N. Ireland

- Contact:

Re: what's best way to clean up aluminum parts?

I found using diesel or paraffin with a dish brush make a nice job of bigger parts. I'd not clean carbs or the like with it though. I just did the gearbox casing, rocker covers, remote gear linkage and the like.

Ian Campbell

-

foxy52

- 1275 Cooper S

- Posts: 1114

- Joined: Wed Nov 02, 2011 10:44 am

Re: what's best way to clean up aluminum parts?

...Auto Sol.. the orig and the best .....foxy52bpirie1000 wrote:Auto sol and elbow grease fine wet and dry paper...

Maybe I am a sucker for punishment

Re: what's best way to clean up aluminum parts?

Bead blasting with fine glass beads (or as I prefer to call that stuff "glass flour") works also very well! I rebuilt a set of twin HS2 carbs some time ago and the result was outstanding!

I think there are a lot of parameters where one could influence the process of bead blasting, as you could choose different grits of blasting material (respectively different grits/sizes of beads), then you have to try which air pressure gives you the best result and finally the nozzle of the blasting gun influences the surface also quite a bit... So enough "adjusting screws" to either get a very good result or mess it totally up!

For example a company, I worked for a few years ago, had a blasting cabinet which they used for bead blasting parts they cut from stainless steel. The result was very good on this kind of material. As I asked the guy who was using the blasting cabinet what parameters he is using (out of interest, because at that time I just had bought myself a small blasting cabinet, but hadn´t used it then) he told me what I wanted to know and asked why I asked him that and if I needed something bead blasted. I told him of the carburetors and he said: "Oh, thats no problem. If we blast them here, they´ll be like new afterwards!" Despite the offer, I did not want to bring my own stuff with me to work and misapply their tools. Later as I had learned some things about bead blasting I realized something. Guess what? The grade of beads they used in their cabinet would have totally ruined my set of carbs if I´d brought them there...

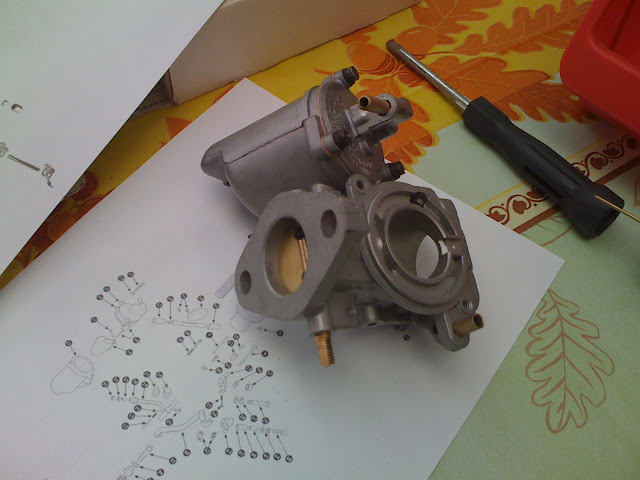

But it is like it is often in life, there isn´t just "that one" way to do things, there are often a lot of possible ways. The set I currently have on my workbench gets a totally different treatment. It was first cleaned in a cold cleaning solvent (not as volatile as petrol or paint thinner, more like diesel) by brushing and "soaking" it thoroughly, then i rubbed it clean and removed the remaining grime (e.g. small spots of paint or other persistent remains) with paint thinner and brake cleaner. And the result is very close to the bead blasting!

The only difference I could notice was that the glass bead blasting is better in cleaning up slight discolorations on the surface (but without really getting the surface structure destroyed, as it was afterwards as smooth as before!)

Cheers, Mike

I think there are a lot of parameters where one could influence the process of bead blasting, as you could choose different grits of blasting material (respectively different grits/sizes of beads), then you have to try which air pressure gives you the best result and finally the nozzle of the blasting gun influences the surface also quite a bit... So enough "adjusting screws" to either get a very good result or mess it totally up!

For example a company, I worked for a few years ago, had a blasting cabinet which they used for bead blasting parts they cut from stainless steel. The result was very good on this kind of material. As I asked the guy who was using the blasting cabinet what parameters he is using (out of interest, because at that time I just had bought myself a small blasting cabinet, but hadn´t used it then) he told me what I wanted to know and asked why I asked him that and if I needed something bead blasted. I told him of the carburetors and he said: "Oh, thats no problem. If we blast them here, they´ll be like new afterwards!" Despite the offer, I did not want to bring my own stuff with me to work and misapply their tools. Later as I had learned some things about bead blasting I realized something. Guess what? The grade of beads they used in their cabinet would have totally ruined my set of carbs if I´d brought them there...

But it is like it is often in life, there isn´t just "that one" way to do things, there are often a lot of possible ways. The set I currently have on my workbench gets a totally different treatment. It was first cleaned in a cold cleaning solvent (not as volatile as petrol or paint thinner, more like diesel) by brushing and "soaking" it thoroughly, then i rubbed it clean and removed the remaining grime (e.g. small spots of paint or other persistent remains) with paint thinner and brake cleaner. And the result is very close to the bead blasting!

The only difference I could notice was that the glass bead blasting is better in cleaning up slight discolorations on the surface (but without really getting the surface structure destroyed, as it was afterwards as smooth as before!)

Cheers, Mike

Re: what's best way to clean up aluminum parts?

And now I´ve dug out a few pictures from the work I´ve done to carburetors. These are just some pictures of the bead blasting and none of the "conventionally" cleaned parts...

That´s a LH carb body after bead blasting, as it came out of the blasting cabinet.

And that is the same carb at the time of assembly. You can clearly see how clean everything is!

Then I made a pic for comparison. What a difference that made! (And yes, I do know that the floating chamber lid on the fresh assembled carb is bolted down in the wrong position!

(And yes, I do know that the floating chamber lid on the fresh assembled carb is bolted down in the wrong position!

)

)

That´s a LH carb body after bead blasting, as it came out of the blasting cabinet.

And that is the same carb at the time of assembly. You can clearly see how clean everything is!

Then I made a pic for comparison. What a difference that made!

-

surfblue63

Re: what's best way to clean up aluminum parts?

These were cleaned with an ultrasonic bath and a tooth brush. I used one of those 5 litre baths that you get on Ebay. If you want a factory finish then I think it is the best way to get it.

- Dr.Mabo

- 998 Cooper

- Posts: 500

- Joined: Wed Jun 27, 2012 1:05 pm

- Location: Germany

- Been thanked: 6 times

Re: what's best way to clean up aluminum parts?

Here are the announced before & after pics of my HS2 cabs, which I did in 2002.mk1 wrote:I would like to see the before & after pics.

It was the first time I used "AL80" and I'm still very pleased with the result.

so long

the Doc

You do not have the required permissions to view the files attached to this post.

-

Ollie78

- 850 Super

- Posts: 178

- Joined: Sun Sep 15, 2013 8:50 pm

Re: what's best way to clean up aluminum parts?

I have media blasted a few alloy bits and pieces, small scale. Its important to get the right media for the job, removing the soiling/corrosion without damaging the substrate means ideally the blast media is slightly softer than the substrate base material. As has already been suggested walnut shell should work well, I used calcite (marble dust) which was probably a bit too hard on alloy but it came out OK with a careful blast.

-

Chalkie

Re: what's best way to clean up aluminum parts?

Nice got a few ideas

I ideally didn't want to have any form of blasting done because its just expensive

ill polish the dash pots by hand autosol is best stuff

I ideally didn't want to have any form of blasting done because its just expensive

ill polish the dash pots by hand autosol is best stuff

- smithyrc30

- 1275 Cooper S

- Posts: 1383

- Joined: Thu Feb 05, 2015 8:40 am

Re: what's best way to clean up aluminum parts?

Personally I use hydro or aquablasting on aluminium parts. I believe hydro blasting was invented by Rolls Royce to clean compressor blades in jet turbines without damaging the surface or blocking the air bleed holes through the blades, although I can not back that up. I read it somewhere but cannot find the source now.

Gas only particle blasting leaves bits of the media embedded into the aluminium surface which does come back out under vibration. I had a set of motorcycle flat slides done with plastic media which I was assured was way too soft to damage or embed.

After running the bike for only a few hundred kilometers it ran very erratically. Removing the carbs revealed tiny bits of the media in the roller bearing surfaces causing the slides to stick. Not what you want. The carbs were ruined and I had to source another set.

I will only use ultra sonic or water blasting now for aluminium, soda or walnut is fine on steel and coconut husk is good on fibre glass to remove paint without damaging the gel coat. Sand or grit should not be used near machined surfaces in my opinion and I wouldn't use it on body parts either, it is too abrasive.

Cheers

Gas only particle blasting leaves bits of the media embedded into the aluminium surface which does come back out under vibration. I had a set of motorcycle flat slides done with plastic media which I was assured was way too soft to damage or embed.

After running the bike for only a few hundred kilometers it ran very erratically. Removing the carbs revealed tiny bits of the media in the roller bearing surfaces causing the slides to stick. Not what you want. The carbs were ruined and I had to source another set.

I will only use ultra sonic or water blasting now for aluminium, soda or walnut is fine on steel and coconut husk is good on fibre glass to remove paint without damaging the gel coat. Sand or grit should not be used near machined surfaces in my opinion and I wouldn't use it on body parts either, it is too abrasive.

Cheers