Just wanting to know what some of your guys who go Rallying do for mounting your radiators and holding it all together.

I do have a way that I am doing them at present, but crickey it is a LOT of work, surely there must be a simpler / easier way?

Radiators in Rally Cars

-

LMM76C

- 998 Cooper

- Posts: 672

- Joined: Tue Oct 19, 2010 3:35 pm

Re: Radiators in Rally Cars

Simpler and easier than what? - you don't say what you're doing at present. Solid mounting to the bodywork is the best solution but it has to involve use of good engine mountings, good steady bar mountings and a rear gear linkage mounting as solid as the original Mitchell mounting - and I have no idea whether such quality kit is available today.

-

ianh1968

- 1275 Cooper S

- Posts: 1012

- Joined: Sat Nov 03, 2012 6:00 pm

- Location: West Sussex

Re: Radiators in Rally Cars

Until I devised this very simple solution, I was always

shaking my rads to pieces. It's a road car, but I guess

that it's still relevant?

It's based on the later single-piece cowel... Sorry about the sh!t photo, it was pitch black at the time

and it was illuminated only by the flash.

I completely junk the standard top mount, and replace it

with a simple "strut". Each end is rubber mounted, the rad

end has a double ended M6 rubber whatsit, and the other

end a 5/16" UNF exhaust bobbin-type-of-thing...

The strut itself is just a bit of 1/16" thick stainless sheet...

The engine end is screwed to the "MiniSpares" left-hand

engine steady bracket, one of these...

http://www.minispares.com/product/Class ... o%20search

The front "rubber mount", (not shown) is the stat housing

to rad elbow-pipe!

Haven't changed a rad for years, apart from upgrading to an

ally type one recently.

Ian

shaking my rads to pieces. It's a road car, but I guess

that it's still relevant?

It's based on the later single-piece cowel... Sorry about the sh!t photo, it was pitch black at the time

and it was illuminated only by the flash.

I completely junk the standard top mount, and replace it

with a simple "strut". Each end is rubber mounted, the rad

end has a double ended M6 rubber whatsit, and the other

end a 5/16" UNF exhaust bobbin-type-of-thing...

The strut itself is just a bit of 1/16" thick stainless sheet...

The engine end is screwed to the "MiniSpares" left-hand

engine steady bracket, one of these...

http://www.minispares.com/product/Class ... o%20search

The front "rubber mount", (not shown) is the stat housing

to rad elbow-pipe!

Haven't changed a rad for years, apart from upgrading to an

ally type one recently.

Ian

You do not have the required permissions to view the files attached to this post.

- Spider

- 1275 Cooper S

- Posts: 4805

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 125 times

- Been thanked: 34 times

Re: Radiators in Rally Cars

ianh1968, thank you for going to the trouble of getting photos and your excellent description of what you've done.

Yeah, I'd say that would be quite OK for up to hard road use.

I tend to travel on less than good roads, or tracks really, and many of them are very long, usually over 500 km in length, they are often not maintained and heavily corrugated, so vibration is fairly heavy and constant to say the least.

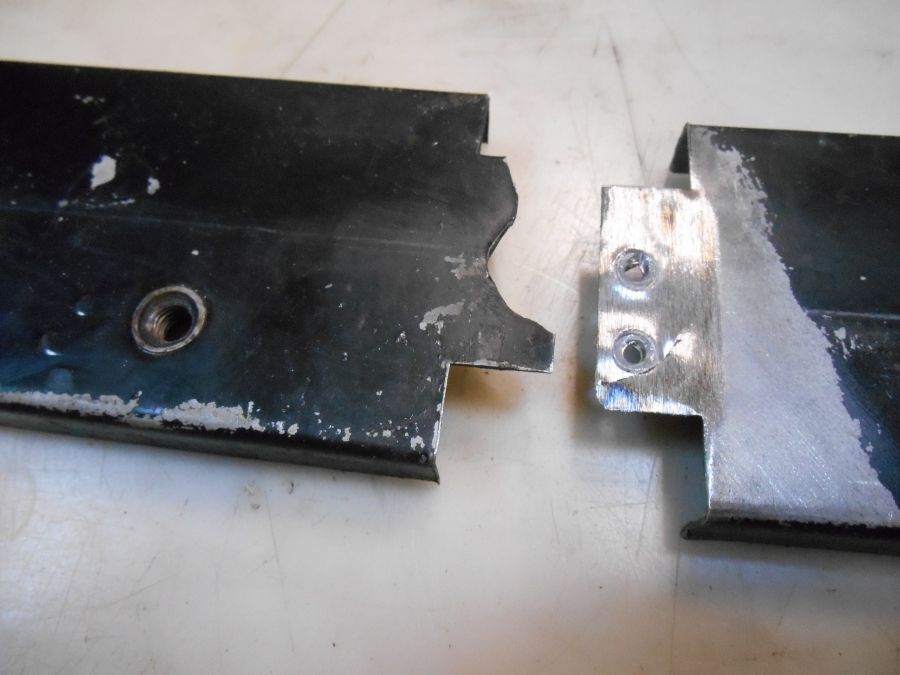

I have tried solid mounting the radiator to the body in the past, however it means either running without a cowling or shortening the fan blades about 12 - 15 mm, neither of these are an option when driving slow (like through sand dunes) and / or ambient temps are over about 42 degrees. I also found that while the mounting is quite good, the sides of the radiators crack off, like this

and just caught this one in time

That was after only 1 trip, just over 9000 kM.

For an engine steady, I have been doing my own, which is a bit of a variation of the ones that were factory fitted (in Aust at least) and you can (just) see it here;-

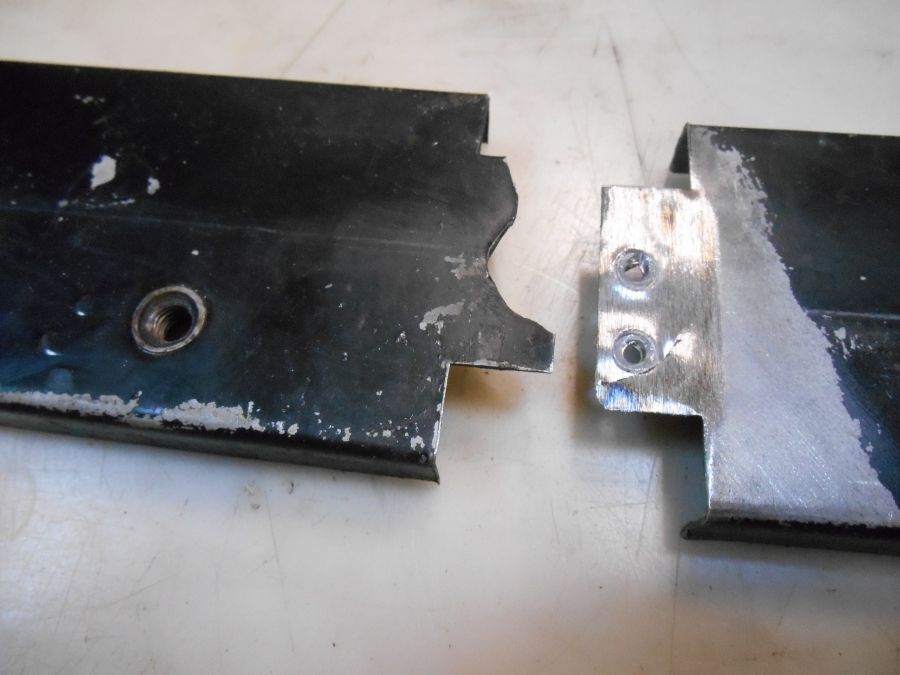

We never got the 1 piece cowling out here, though there are a few kicking about. Regardless, I have found both to be just too thin and these also crack;-

So, now I am making my own cowlings, from 1.5 mm sheet and they are a fair bit of work to get just right;

(you can see this one fitted in the top photo)

and we are also having to make new sides for our new radiators

So far, we find this works but as per my opening post, they are a LOT of work and surely there must be a simpler / easier way?

Yeah, I'd say that would be quite OK for up to hard road use.

I tend to travel on less than good roads, or tracks really, and many of them are very long, usually over 500 km in length, they are often not maintained and heavily corrugated, so vibration is fairly heavy and constant to say the least.

I have tried solid mounting the radiator to the body in the past, however it means either running without a cowling or shortening the fan blades about 12 - 15 mm, neither of these are an option when driving slow (like through sand dunes) and / or ambient temps are over about 42 degrees. I also found that while the mounting is quite good, the sides of the radiators crack off, like this

and just caught this one in time

That was after only 1 trip, just over 9000 kM.

For an engine steady, I have been doing my own, which is a bit of a variation of the ones that were factory fitted (in Aust at least) and you can (just) see it here;-

We never got the 1 piece cowling out here, though there are a few kicking about. Regardless, I have found both to be just too thin and these also crack;-

So, now I am making my own cowlings, from 1.5 mm sheet and they are a fair bit of work to get just right;

(you can see this one fitted in the top photo)

and we are also having to make new sides for our new radiators

So far, we find this works but as per my opening post, they are a LOT of work and surely there must be a simpler / easier way?

Re: Radiators in Rally Cars

If you mount the rad to the body, it all has to be mounted to the shell. You can't have the bottom still attached to the engine mount, or it will crack. With it mounted to the shell, you need to use the most flexible hoses you can find.

-

LMM76C

- 998 Cooper

- Posts: 672

- Joined: Tue Oct 19, 2010 3:35 pm

Re: Radiators in Rally Cars

Specifically it is mounted to two strong (ie. quite thick) aluminium "sides" that you fix permanently to the extended radiator "hole" in the bodywork, drilled to take the standard radiator side bolts (it even works with early type screw/clip radiators that pre date the captive nut type). The radiator sits exactly where it does as standard so no clearance problems and better access. As I posted earlier, the engine must be mounted as firmly as was ever possible. The "Mitchel" mounting for the gear linkage extension was vital to this. A standard mounting allowed the engine to rock far too much and loosen hoses. If engine is mounted firmly enough, standard hoses are perfectly adequate.

There was always a grey area regarding Group 2 homologation for dispensing with the standard rad shroud and I don't think the works did it in Gp2 but I know of no private entrant (including me) ever being picked up on it.

There was always a grey area regarding Group 2 homologation for dispensing with the standard rad shroud and I don't think the works did it in Gp2 but I know of no private entrant (including me) ever being picked up on it.

- miniminor

- 1275 Cooper S

- Posts: 814

- Joined: Thu Sep 27, 2012 6:49 pm

- Location: Upside down behind the TV

- Been thanked: 2 times

Re: Radiators in Rally Cars

"Get the wheels in line, Get the wheels in line with it! ..... and then slam your brakes on or we'll be in the cabin ! "

1963 Morris Mini Minor Superdeluxe

2014 Freelander 2 SD4

1963 Morris Mini Minor Superdeluxe

2014 Freelander 2 SD4

- Spider

- 1275 Cooper S

- Posts: 4805

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 125 times

- Been thanked: 34 times

Re: Radiators in Rally Cars

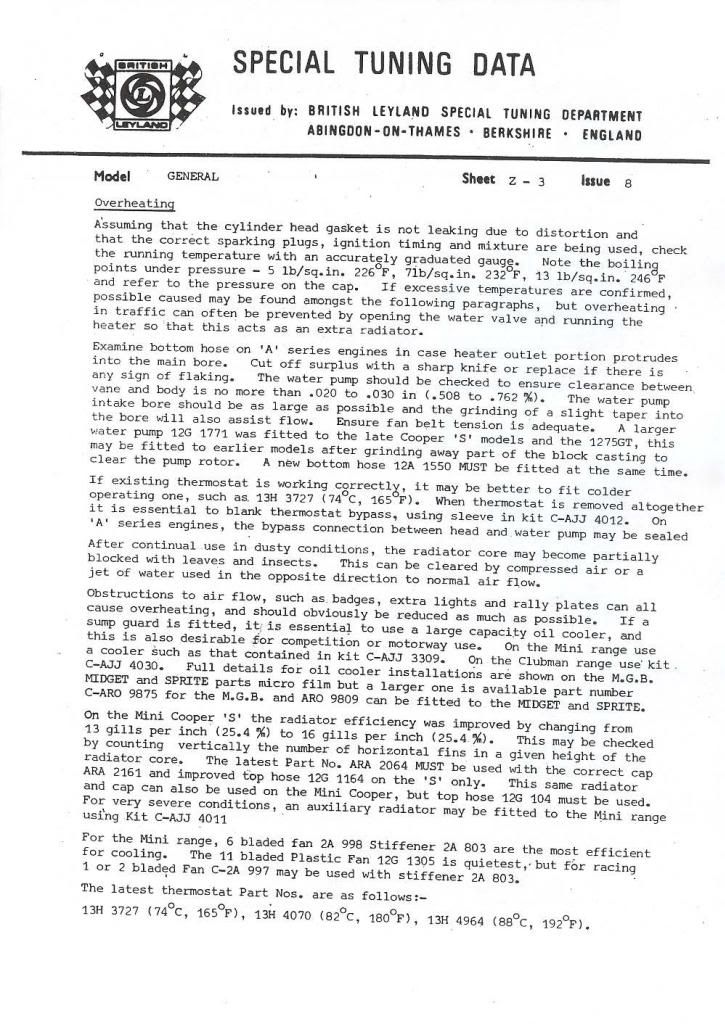

I think they call them an 'Export Fan', it has 6 big muthu blades. They push the most air of any factory fan. I think there is a reference to them in some of the ST Publications.

edit> found it;-

I note they say to use a stiffener. I've been using these fans for a very long time now and I have to say, I've never used a stiffener with any of them.

edit> found it;-

I note they say to use a stiffener. I've been using these fans for a very long time now and I have to say, I've never used a stiffener with any of them.