Are the rod change assemblies on Mini's and Metro's the same ?

Need one for my pick up project, can't find one here but know where a Metro one is ?

Anyone ?

Cheers

Andrew

Mini and Metro rod change assemblies

- Andrew1967

- 1275 Cooper S

- Posts: 7911

- Joined: Thu Jun 24, 2010 6:35 pm

- Location: Usually in my garage on the east coast of Norfolk, UK

- Been thanked: 5 times

-

steve65

- 850 Super

- Posts: 149

- Joined: Sun Nov 28, 2010 2:41 pm

- Andrew1967

- 1275 Cooper S

- Posts: 7911

- Joined: Thu Jun 24, 2010 6:35 pm

- Location: Usually in my garage on the east coast of Norfolk, UK

- Been thanked: 5 times

Re: Mini and Metro rod change assemblies

Thanks for the quick replies.

That's put the kybosh on the Metro set up. Good to know where to get one if I don't locate one closer to home

Andrew

That's put the kybosh on the Metro set up. Good to know where to get one if I don't locate one closer to home

Andrew

-

ianh1968

- 1275 Cooper S

- Posts: 1012

- Joined: Sat Nov 03, 2012 6:00 pm

- Location: West Sussex

Re: Mini and Metro rod change assemblies

Why? With a hacksaw and a mig-welder this would be an easy mod...Andrew1967 wrote:That's put the kybosh on the Metro set up. Andrew

Saw the assembly off to an appropriate length and make tubes to

join up the bits... You could even do a dummy run prior to welding

by using some kind of grub-screw arrangement in the "tubes"...

You may even be able to modify the angle of the gear-lever,

within sensible limits...

I have a Mini-Marcos and have absolutely no idea what car my Dad

got the gear linkage off, all I know is that there is an extra-long

fabricated joiner "thingy" between the bottom rod and the gearbox.

(You know, the one with the sh!tty roll pins in it!)

Another thing: The roll pins - You would be surprised how much "slack"

you can remove by changing these to something more "solid"...

Using nitrided mould-ejection pins instead of roll pins results in a much

more "direct" feeling gear-change. A "second-best" would be to use

a suitable size of engineering shoulder-screw in place of the roll-pins.

Something like these:

http://www.automotioncomponents.co.uk/e ... rews/p0136

(6mm OD,25mm length, M5 thread)

You might have to change the shape of the "pan" head at the gearbox

end into a "mushroom", but I've done this before by putting the bolt in

an electric hand-drill and "turning" the head with a file...

My Dad, being a toolmaker, went for the nitrided mould-pin idea, but

me, being a mere mortal, had to settle for the shoulder screw idea.

Both concepts will noticably improve the feel of the gearchange, but

may require the (possibly expensive) boring out of the relevant parts

to an appropriate size.

Ian

Last edited by ianh1968 on Wed Nov 04, 2015 10:40 pm, edited 1 time in total.

- Andrew1967

- 1275 Cooper S

- Posts: 7911

- Joined: Thu Jun 24, 2010 6:35 pm

- Location: Usually in my garage on the east coast of Norfolk, UK

- Been thanked: 5 times

Re: Mini and Metro rod change assemblies

Good thinking Ian,

If I can get the correct lengths, cutting and re welding is no problem

Thanks for the ideas on upgrading the roll pins - will look into that when the time comes.

Cheers

Andrew

If I can get the correct lengths, cutting and re welding is no problem

Thanks for the ideas on upgrading the roll pins - will look into that when the time comes.

Cheers

Andrew

-

ianh1968

- 1275 Cooper S

- Posts: 1012

- Joined: Sat Nov 03, 2012 6:00 pm

- Location: West Sussex

Re: Mini and Metro rod change assemblies

These were was not my ideas, the mould-pin idea was my Dad's, requiring spark-eroded holes for R-Clips to retain the pins.Andrew1967 wrote:Thanks for the ideas on upgrading the roll pins - will look into that when the time comes.

The shoulder screw concept was subsequent and came from another very skilled toolmaker...

Ian

-

ianh1968

- 1275 Cooper S

- Posts: 1012

- Joined: Sat Nov 03, 2012 6:00 pm

- Location: West Sussex

Re: Mini and Metro rod change assemblies

PS:

The shoulder-screw idea is probably more practical as you can

quite easily buy new screws, whereas the bomb-proof mould-pin

concept would require spark-erosion of some clip holes at any

time new pins are needed... (Which would probably be never!).

Once you've bored/ground out all necessary holes to 6mm,

using shoulder screws is much easier. The ones I have used

have a 3mm internal (Allen) hex, and if they do jam up, at least

you can get a set of mole-grips on the heads to loosen them off.

... much easier that trying to whack out roll-pins...

Ian

The shoulder-screw idea is probably more practical as you can

quite easily buy new screws, whereas the bomb-proof mould-pin

concept would require spark-erosion of some clip holes at any

time new pins are needed... (Which would probably be never!).

Once you've bored/ground out all necessary holes to 6mm,

using shoulder screws is much easier. The ones I have used

have a 3mm internal (Allen) hex, and if they do jam up, at least

you can get a set of mole-grips on the heads to loosen them off.

... much easier that trying to whack out roll-pins...

Ian

- Spider

- 1275 Cooper S

- Posts: 4805

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 125 times

- Been thanked: 34 times

Re: Mini and Metro rod change assemblies

Nice idea with the tubes and grub screws, I like.ianh1968 wrote:Why? With a hacksaw and a mig-welder this would be an easy mod...Andrew1967 wrote:That's put the kybosh on the Metro set up. Andrew

Saw the assembly off to an appropriate length and make tubes to

join up the bits... You could even do a dummy run prior to welding

by using some kind of grub-screw arrangement in the "tubes"...

You may even be able to modify the angle of the gear-lever,

within sensible limits...

I have a Mini-Marcos and have absolutely no idea what car my Dad

got the gear linkage off, all I know is that there is an extra-long

fabricated joiner "thingy" between the bottom rod and the gearbox.

(You know, the one with the sh!tty roll pins in it!)

Another thing: The roll pins - You would be surprised how much "slack"

you can remove by changing these to something more "solid"...

Using nitrided mould-ejection pins instead of roll pins results in a much

more "direct" feeling gear-change. A "second-best" would be to use

a suitable size of engineering shoulder-screw in place of the roll-pins.

Something like these:

http://www.automotioncomponents.co.uk/e ... rews/p0136

(6mm OD,25mm length, M5 thread)

You might have to change the shape of the "pan" head at the gearbox

end into a "mushroom", but I've done this before by putting the bolt in

an electric hand-drill and "turning" the head with a file...

My Dad, being a toolmaker, went for the nitrided mould-pin idea, but

me, being a mere mortal, had to settle for the shoulder screw idea.

Both concepts will noticably improve the feel of the gearchange, but

may require the (possibly expensive) boring out of the relevant parts

to an appropriate size.

Ian

One thing if you do end up cutting and shutting, take lots of time to get the lower rod, with the holes for the Roll Pins, lined up as exact as you can, otherwise, the lever will be cocked over one side or the other. It only takes a small amount to be out,,,,, To help line them up, stand some drill bits (7/32") in both holes so you can sight off those. I've not had to make longer ones, but I have made shorter rods, I always drill them in the mill to get them spot on.

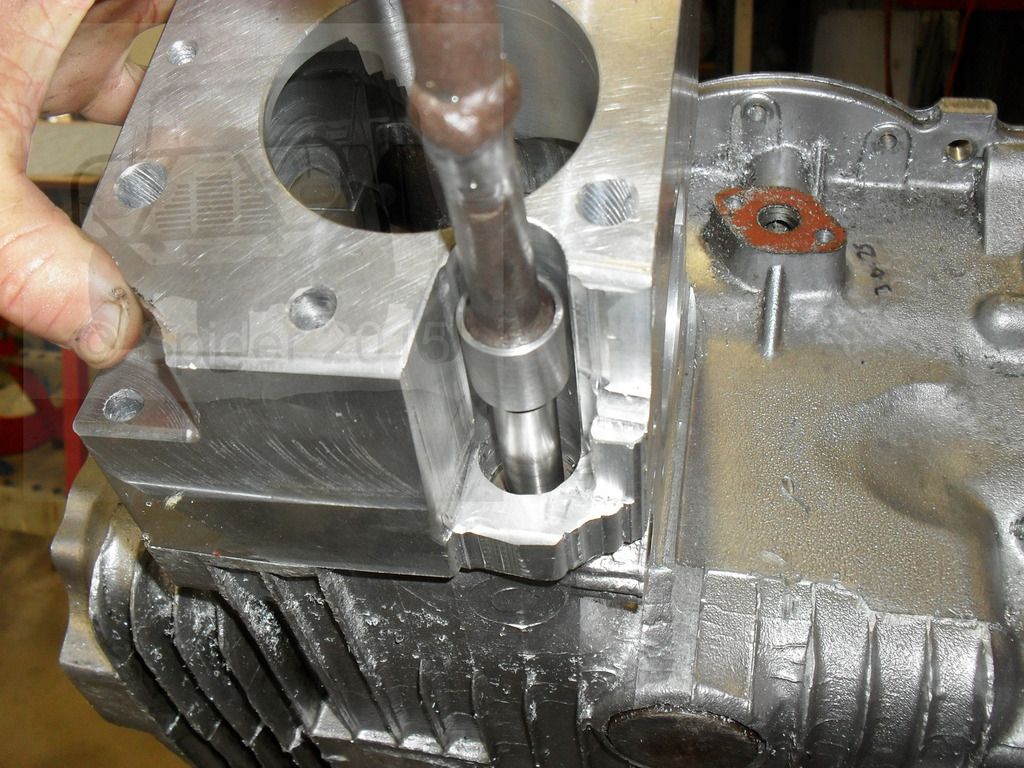

Ian, Bhaha, great minds,,,, When I did the 4WD Gearbox, there was room to get a Roll Pin in, but not get it out, so I got some 5.5 mm Hardened Pins (just hardened, I didn't go all out with Nitrided Pins!) and turned up a Sleeve which slipped over the coupling, to hold the pins in. The Sleeve in turn was held on to the coupling with an M4 screw. This is it before the M4 screw was added;-

So, now, (at least on this one), there's no more BASH BASH BASH to get the pins in or out, merely undo the screw, slip the sleeve back and the pin falls out, or may need help from a magnet.

One thing that does make the Roll Pins wear faster is that nearly always, there's some Oil on the shift rod (OK, some have a lot) and this only attracts the dirt right inside the coupling,,,,,,