Problems with MiniSpares top hat bushes?

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Problems with MiniSpares top hat bushes?

I ordered a pair of primary gear bushes from MiniSpares a couple of months ago. I got the old ones out fairly easily last night, and installed the new ones tonight. The fully-floating bush went in perfectly, and looks like it will work well.

The top hat bush was more difficult to press in than I expected, but the real problem came when I attempted to slide it onto the tail of the crank.....it wasn't even CLOSE to sliding onto the crank. I measured the crank tail, and it measured at 1.500". I measured the ID of the installed top hat bush, and it was 1.475"....a full 0.025" smaller than the crank. I measured a couple of used ones that I had handy, and they measured 1.502-3", as you would expect. This means the bush is at least 0.027" undersized.

I was under the impression this bush didn't need to be honed....was I badly mistaken?

The top hat bush was more difficult to press in than I expected, but the real problem came when I attempted to slide it onto the tail of the crank.....it wasn't even CLOSE to sliding onto the crank. I measured the crank tail, and it measured at 1.500". I measured the ID of the installed top hat bush, and it was 1.475"....a full 0.025" smaller than the crank. I measured a couple of used ones that I had handy, and they measured 1.502-3", as you would expect. This means the bush is at least 0.027" undersized.

I was under the impression this bush didn't need to be honed....was I badly mistaken?

Last edited by Benny on Thu Jul 11, 2013 5:45 am, edited 1 time in total.

- Spider

- 1275 Cooper S

- Posts: 4858

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 199 times

- Been thanked: 75 times

Re: Problems with MiniSpares top hat bushes?!

OK, now, I gotta say, I'm not a fan of the floating bushes, they seem a little harder on the crank tails than the bronze ones. Maybe just me, but that's been my experience, I do know they are popular.

Now, the rear (top hat) bush. The stock bushes (both front and rear) MUST be fitted by freezing them in dry ice, forget the freezer, it's just not cold enough. I leave them in the dry ice for around an hour to get them right down in temp. I also warm the Primary Gears on a hot plate at low temp (~ 40 - 50 degrees) for a similar amount of time, just so they are almost top hot to handle, then slip them together, no pressing needed. I think the factory do say to use dry ice on the bushes. If you don't do them this way, then they will spin in the gear, no question, as the bush will ream itself on the way in, only on the outside!

They also require machining after fitting (I like to leave them over night after fitting to stabalise in temp). Running clearance is 0.003 to 0.0045". I aim for the lower end as this gives a greater surface area, therefore, lower loading, so they last longer. Now, most important, after machining, they need to be hot oil soaked. Heat some non friction modified non synthetic oil to around 80 degrees and drop the gear in there for around 8 hours. I have an old small deep fryer that I use for doing this. This is needed as after assembly, no more oil will ever (or should ever!) get in to the bushes for lubrication. Being Phosphor Bronze, it will absorb oil when hot and so provides lubrication for the life of the bush. Do this and you will get very good life out of them.

Now, the rear (top hat) bush. The stock bushes (both front and rear) MUST be fitted by freezing them in dry ice, forget the freezer, it's just not cold enough. I leave them in the dry ice for around an hour to get them right down in temp. I also warm the Primary Gears on a hot plate at low temp (~ 40 - 50 degrees) for a similar amount of time, just so they are almost top hot to handle, then slip them together, no pressing needed. I think the factory do say to use dry ice on the bushes. If you don't do them this way, then they will spin in the gear, no question, as the bush will ream itself on the way in, only on the outside!

They also require machining after fitting (I like to leave them over night after fitting to stabalise in temp). Running clearance is 0.003 to 0.0045". I aim for the lower end as this gives a greater surface area, therefore, lower loading, so they last longer. Now, most important, after machining, they need to be hot oil soaked. Heat some non friction modified non synthetic oil to around 80 degrees and drop the gear in there for around 8 hours. I have an old small deep fryer that I use for doing this. This is needed as after assembly, no more oil will ever (or should ever!) get in to the bushes for lubrication. Being Phosphor Bronze, it will absorb oil when hot and so provides lubrication for the life of the bush. Do this and you will get very good life out of them.

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Re: Problems with MiniSpares top hat bushes?!

Ok, so it sounds like i was wrong about the rear bush being a plug-and-play afair.Spider wrote:

They also require machining after fitting (I like to leave them over night after fitting to stabalise in temp). Running clearance is 0.003 to 0.0045". I aim for the lower end as this gives a greater surface area, therefore, lower loading, so they last longer. Now, most important, after machining, they need to be hot oil soaked. Heat some non friction modified non synthetic oil to around 80 degrees and drop the gear in there for around 8 hours. I have an old small deep fryer that I use for doing this. This is needed as after assembly, no more oil will ever (or should ever!) get in to the bushes for lubrication. Being Phosphor Bronze, it will absorb oil when hot and so provides lubrication for the life of the bush. Do this and you will get very good life out of them.

I've read plenty of scaremongering that seems to indicate that machining the bushings properly, and maintaining concentricity, is nearly impossible for your "average" machinist. Do you have a special set-up for doing this?

- Spider

- 1275 Cooper S

- Posts: 4858

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 199 times

- Been thanked: 75 times

Re: Problems with MiniSpares top hat bushes?

I do mine in the lathe on a 4 jaw chuck, so I can clock up (centre) the gear before machining.

- Vegard

- 1275 Cooper S

- Posts: 2042

- Joined: Mon Jun 28, 2010 1:33 pm

- Location: Norway

- Contact:

Re: Problems with MiniSpares top hat bushes?

Yes you were!Benny wrote: I was under the impression this bush didn't need to be honed....was I badly mistaken?

It needs to be reamed, not honed btw.

-

guru_1071

- 1275 Cooper S

- Posts: 2109

- Joined: Thu Jun 24, 2010 7:47 pm

Re: Problems with MiniSpares top hat bushes?

the bushes must be sized to suit the crank and the application that its been used for

I always heat the primary in the oven and soak it in oil before fitting it (if its had new bushes) as its important to get a load of oil into the bushes

I always heat the primary in the oven and soak it in oil before fitting it (if its had new bushes) as its important to get a load of oil into the bushes

please note, these are my own, individual sales, nothing whatsoever to do with my employer, minispares

- pad4

- 1275 Cooper S

- Posts: 1090

- Joined: Sun Jun 27, 2010 5:57 am

- Location: Darwen, Lancashireee

Re: Problems with MiniSpares top hat bushes?

THIS IS WHY WE CANT LOOSE THIS FORUM

Excellent info guys

PAD

Excellent info guys

PAD

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Re: Problems with MiniSpares top hat bushes?

Thanks Rich,guru_1071 wrote:the bushes must be sized to suit the crank and the application that its been used for

I had another question related to the use of a fully floating bush in an A+ gear. The write-up on the website says that the fully-floating bushes not for the A+, but I've heard from several people who have put them in A+ gears, and the bushing physically fits just fine.

The write-up also goes on to talk about how the drilled oil holes can shred the fully-floating bush by working as cutting teeth if they are drilled at an angle. It goes on to say "This is how most A+ gears were drilled", so is this the reason the ad says they are not for the A+?

Further to this, I looked at both of my A+ gears, and also a pre-A+ gear, and can't see any difference in this respect. All three have their holes drilled at an angle, and have those "cutting teeth" that would presumably have the potential to damage the bush if it pressed up against the lip, and spun.

I can post a picture of what my gear looks like, but is there a picture of a gear that is "desirable" for use with the fully-floating bush?

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Re: Problems with MiniSpares top hat bushes?

These pictures illustrate what I was TRYING to ask Rich. With the bushing removed from an A+ gear, you can see the "cutting teeth" formed by the oil holes (first pic) as mentioned on the MiniSpares website. With te fully-floating bushing in place, I guess you could see how those holes could damage the bushing if it pushed up against those holes (second pic) with any force, and spun.

However, my question is why the MS website highlights that issue for an A+ gear, when I don't see much difference on a Pre A+ gear (third pic).

However, my question is why the MS website highlights that issue for an A+ gear, when I don't see much difference on a Pre A+ gear (third pic).

You do not have the required permissions to view the files attached to this post.

-

guru_1071

- 1275 Cooper S

- Posts: 2109

- Joined: Thu Jun 24, 2010 7:47 pm

Re: Problems with MiniSpares top hat bushes?

benny

its an easy answer

in the pre a plus gears, there is a step which prevents the floater from covering up the holes and stopping the oil flow.

this step isn't present in all plus gears, some have a slight 'lead in' which works as a back stop for the floater, but some don't even have this and this will chew the floater up a little, then, I guess it will cover the holes and cut the oil flow, which allows it to seize onto the crank.

its an easy answer

in the pre a plus gears, there is a step which prevents the floater from covering up the holes and stopping the oil flow.

this step isn't present in all plus gears, some have a slight 'lead in' which works as a back stop for the floater, but some don't even have this and this will chew the floater up a little, then, I guess it will cover the holes and cut the oil flow, which allows it to seize onto the crank.

please note, these are my own, individual sales, nothing whatsoever to do with my employer, minispares

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Re: Problems with MiniSpares top hat bushes?

Thanks Rich,

In my case, the floater can only partially cover the holes. In the instructions that were in the bag with the bush, it said something along the lines of "don't worry if the holes are partially covered, as oil will find its way in".

Does it sound like I'm likely ok in my case?

In my case, the floater can only partially cover the holes. In the instructions that were in the bag with the bush, it said something along the lines of "don't worry if the holes are partially covered, as oil will find its way in".

Does it sound like I'm likely ok in my case?

-

guru_1071

- 1275 Cooper S

- Posts: 2109

- Joined: Thu Jun 24, 2010 7:47 pm

Re: Problems with MiniSpares top hat bushes?

you will be ok, the really bads ones cover the whole holes up

please note, these are my own, individual sales, nothing whatsoever to do with my employer, minispares

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Re: Problems with MiniSpares top hat bushes?

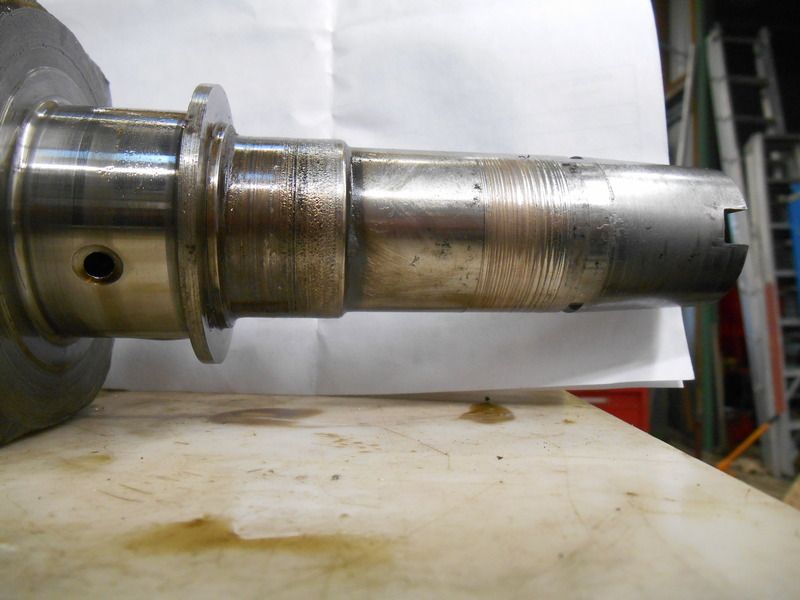

Here's how my tool-maker buddy went about boring out my top-hat bush. Since I'm going to bule using the fully-floating front bush, he decided to pick-ip on the bore of that gear journal. First, he made an aluminum stub to simulate the tail of my crank, so that we could check the fit of the crank-to-bush.

Next, he machined an aluminum mandrel that was 0.0015" larger than the bore of the gear. Then, without removing the mandrel, we chilled it down, and warmed the gear up to about 400 F. Then we slid the gear onto the mandrel, and let it cool down. Once they were thermally locked together, we checked the gear runout, which was less than 0.0005".

Then, he bored out the bushing, giving a beautiful fit on the simulated crankshaft tail. Lastly, the gear has been sitting in hot oil for the last 36 hours to ensure the bushing is properly saturated.

Hopefully it works well.....if not, I think we gave it a good try.

Next, he machined an aluminum mandrel that was 0.0015" larger than the bore of the gear. Then, without removing the mandrel, we chilled it down, and warmed the gear up to about 400 F. Then we slid the gear onto the mandrel, and let it cool down. Once they were thermally locked together, we checked the gear runout, which was less than 0.0005".

Then, he bored out the bushing, giving a beautiful fit on the simulated crankshaft tail. Lastly, the gear has been sitting in hot oil for the last 36 hours to ensure the bushing is properly saturated.

Hopefully it works well.....if not, I think we gave it a good try.

You do not have the required permissions to view the files attached to this post.

-

guru_1071

- 1275 Cooper S

- Posts: 2109

- Joined: Thu Jun 24, 2010 7:47 pm

Re: Problems with MiniSpares top hat bushes?

nice work benny

im sure some people will just bash them in with a bit of wood!

im sure some people will just bash them in with a bit of wood!

please note, these are my own, individual sales, nothing whatsoever to do with my employer, minispares

- Spider

- 1275 Cooper S

- Posts: 4858

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 199 times

- Been thanked: 75 times

Re: Problems with MiniSpares top hat bushes?

Funny you should say that.guru_1071 wrote:

im sure some people will just bash them in with a bit of wood!

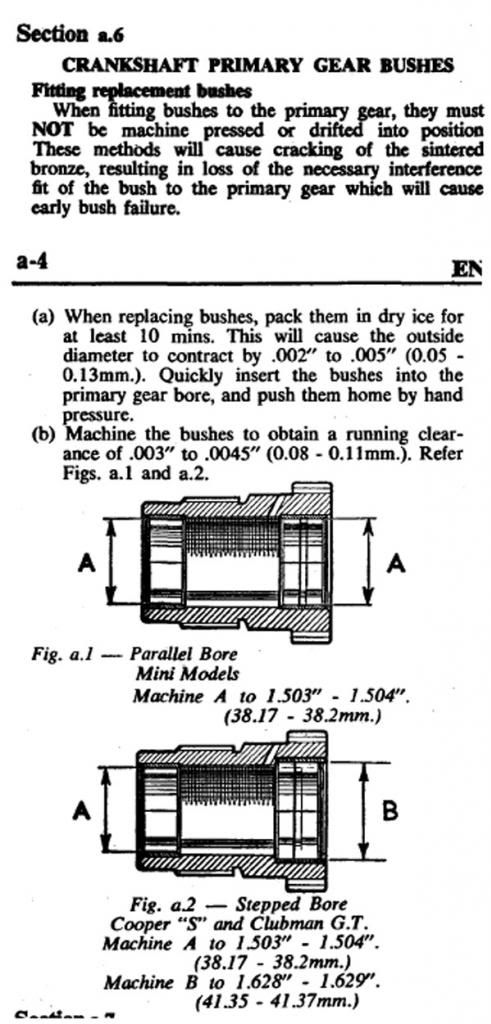

While looking for something else, I came across this in the Australian Factory Workshop Manual (It was over 2 pages, hence why it looks a little odd here)

Interestingly, it doesn't seem to be in the UK books

Last edited by Spider on Sun Jan 26, 2014 9:08 pm, edited 1 time in total.

-

Benny

- 850 Super

- Posts: 225

- Joined: Fri Feb 01, 2013 10:03 pm

- Location: San Diego, CA

Re: Problems with MiniSpares top hat bushes?

Spider,

Part of me wishes you hadn't posted that document. While I did heat up the gear to reduce the interference upon bush installation, I did not chill the bush right down. It pressed in relatively easily on my bench vice, but certainly not with hand pressure. I don't think I put it under any undue stress, but now it's got me wondering.....we shall see.

On a side note, we bored the rear bush to 1.504", so we were on the high end of the tolerance, but within spec. It feels very nice on the shaft once it's all shimmed up for axial play.

Part of me wishes you hadn't posted that document. While I did heat up the gear to reduce the interference upon bush installation, I did not chill the bush right down. It pressed in relatively easily on my bench vice, but certainly not with hand pressure. I don't think I put it under any undue stress, but now it's got me wondering.....we shall see.

On a side note, we bored the rear bush to 1.504", so we were on the high end of the tolerance, but within spec. It feels very nice on the shaft once it's all shimmed up for axial play.

- Spider

- 1275 Cooper S

- Posts: 4858

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 199 times

- Been thanked: 75 times

Re: Problems with MiniSpares top hat bushes?

Saddly - thread revival

OK, so, who had the brain wave of an idea to go away from the Oillite Bushes (for the Top Hat Rear Bush) to Silicon Bronze?

1 - they don't soak up ANY oil what so ever, no matter what we may try, and

2 - the absolute damage they do to the crankshafts is horrendous.

I'll get some photos up tomorrow (if I remember).

The Oillite Bushes are basically powder and machines off as a powder. It is oily to the touch. The Silicon Bronze on the otherhand cuts in longer swirls and is dry to the touch. Totally THE wrong material.

OK, so, who had the brain wave of an idea to go away from the Oillite Bushes (for the Top Hat Rear Bush) to Silicon Bronze?

1 - they don't soak up ANY oil what so ever, no matter what we may try, and

2 - the absolute damage they do to the crankshafts is horrendous.

I'll get some photos up tomorrow (if I remember).

The Oillite Bushes are basically powder and machines off as a powder. It is oily to the touch. The Silicon Bronze on the otherhand cuts in longer swirls and is dry to the touch. Totally THE wrong material.

- Spider

- 1275 Cooper S

- Posts: 4858

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 199 times

- Been thanked: 75 times

Re: Problems with MiniSpares top hat bushes?

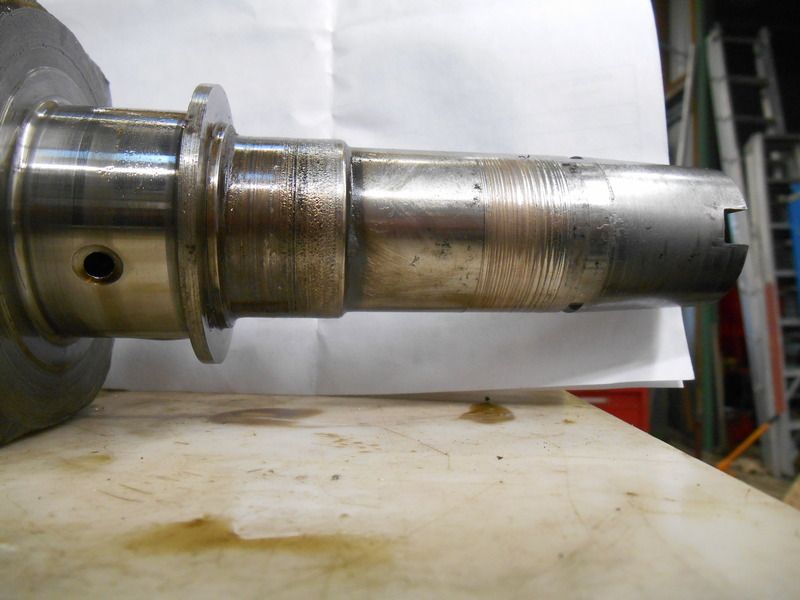

Some photos

The bush still in situ

Bush removed (turned out)

and this is what it did to the crank It now has to be ground and likely custom bushes fitted);

This is a NEW bush, note the extrusion markings;-

Just my thoughts and some investigation work so far.

The material is WAY too hard, and while it can be used in some situations for a bushing material, it is commonly used for fasteners in a marine environment as an alternative to stainless. It also has a fairly high rate of thermal expansion (ie, on the sizes and temps we are dealing with, it can grow 0.004 to 0.005").

It appears that while these materials are around a similar cost, or maybe a little cheaper then the DEVA material, being considerably harder allows the bushes to be pressed in at room temperature, this is not possible with the DEVA material as it will simply crumble away to powder. The correct factory advise relating to the original DEVA bushes is to chill them in Dry Ice, this shrinks them (according to factory info) by 0.003 to 0.005" for fitting. Curiously, I've never found this info an any UK publication, but it was in our Aust Factory Manuals (refer page 1 of this thread)

According to DEVA, the finish is best done as a machining operation (ie, lathe or reamer), where as while the Silicon bronze bushes can be turned, they would benefit from honing, which for a non-ferrous material, is a highly specialised process (and not one most automotive machine shops could do correctly).

The Bronze material can pick up on the shaft of the crank, especially as the bronze is so hard to start with, and this is the beginnings of the failure process seen in this posting, though on another I saw, it also ruined the primary gear. The DEVA material, being basically compressed powder cannot pick up.

As I mentioned before, the Bronze is basically a sealed material (hence why it's so favoured in a marine environment) and cannot accept oil. Grease would appear to be a better lubricant here, however, the speeds involved will cook the grease in short time. If Oil is used, as soon as it runs off, there is no lubrication (and then the bush picks up on the shaft and it's game over). The Bronze to the touch always feels dry.

As we all know, the very early Minis had a Bronzed Bush Primary Gear, yes and all true, however, they also had an Oil Feed to them, which lead to a slipping clutch. The factory spent some considerable time and funds finding a dry running alternative - DEVA.

The DEVA material is already pre-loaded with Graphite and will accept Oil. This material to the touch always seems to have a slipriness about it.

It appears that the floating bushes (fitted to the other end) that are available are of the same material and I have seen a few of these with the same result, not only to the crank, but also the primary gear. Being a Floating Bush, it does not have any support from the Primary Gear and so has to be strong by it's nature. For these types of materials, the strength also comes with high hardness.

OK, Mr. Primary Gear Bush maker(s), can we now get proper bushes again for our Primary Gears?

Disclaimer: No, I don't have any association with DEVA.

The bush still in situ

Bush removed (turned out)

and this is what it did to the crank It now has to be ground and likely custom bushes fitted);

This is a NEW bush, note the extrusion markings;-

Just my thoughts and some investigation work so far.

The material is WAY too hard, and while it can be used in some situations for a bushing material, it is commonly used for fasteners in a marine environment as an alternative to stainless. It also has a fairly high rate of thermal expansion (ie, on the sizes and temps we are dealing with, it can grow 0.004 to 0.005").

It appears that while these materials are around a similar cost, or maybe a little cheaper then the DEVA material, being considerably harder allows the bushes to be pressed in at room temperature, this is not possible with the DEVA material as it will simply crumble away to powder. The correct factory advise relating to the original DEVA bushes is to chill them in Dry Ice, this shrinks them (according to factory info) by 0.003 to 0.005" for fitting. Curiously, I've never found this info an any UK publication, but it was in our Aust Factory Manuals (refer page 1 of this thread)

According to DEVA, the finish is best done as a machining operation (ie, lathe or reamer), where as while the Silicon bronze bushes can be turned, they would benefit from honing, which for a non-ferrous material, is a highly specialised process (and not one most automotive machine shops could do correctly).

The Bronze material can pick up on the shaft of the crank, especially as the bronze is so hard to start with, and this is the beginnings of the failure process seen in this posting, though on another I saw, it also ruined the primary gear. The DEVA material, being basically compressed powder cannot pick up.

As I mentioned before, the Bronze is basically a sealed material (hence why it's so favoured in a marine environment) and cannot accept oil. Grease would appear to be a better lubricant here, however, the speeds involved will cook the grease in short time. If Oil is used, as soon as it runs off, there is no lubrication (and then the bush picks up on the shaft and it's game over). The Bronze to the touch always feels dry.

As we all know, the very early Minis had a Bronzed Bush Primary Gear, yes and all true, however, they also had an Oil Feed to them, which lead to a slipping clutch. The factory spent some considerable time and funds finding a dry running alternative - DEVA.

The DEVA material is already pre-loaded with Graphite and will accept Oil. This material to the touch always seems to have a slipriness about it.

It appears that the floating bushes (fitted to the other end) that are available are of the same material and I have seen a few of these with the same result, not only to the crank, but also the primary gear. Being a Floating Bush, it does not have any support from the Primary Gear and so has to be strong by it's nature. For these types of materials, the strength also comes with high hardness.

OK, Mr. Primary Gear Bush maker(s), can we now get proper bushes again for our Primary Gears?

Disclaimer: No, I don't have any association with DEVA.

- Spider

- 1275 Cooper S

- Posts: 4858

- Joined: Mon May 07, 2012 6:10 am

- Location: Big Red, Australia

- Has thanked: 199 times

- Been thanked: 75 times

Re: Problems with MiniSpares top hat bushes?

Thanks for the kind words there Mark, however while there is quite a bit more yet to come on this, what would be "Excellent" is to once again be able to purchase Deva Bushes to the OEM spec. There are many grades and types of Deva material, selecting the correct one is not at all straight forward (Deja vu?).mk1 wrote:Excellent post Spider!

I am presently in touch with Deva in Germany and also having a local Bearing Design firm look in to this. The local firm have already suggested that while the Bronze based bushes are good, they are not at all what they'd recommend or come up with as a solution for this application. More or less in line with my own knowledge, they have said for something like this, a method of lubrication is needed by either oil feed or grease, but definitely cannot be used 'dry run' and it is a sealed type of material, so hot oil soaking until the cows come home won't help either. In regards to Deva, I'm hoping that someone there may know what was being supplied to BMC / Leyland / Rover rather than having to re-invent the wheel.